Search

The Renewable Energy site for Do-It-Yourselfers

Solar Pond Water

Heater -- Construction

|

The pictures below show the

construction of the solar pond water heater prototype 3.

The parts:

|

|

Pond Frame,

Insulation, and Liner

You need to have a flat place that

stays relatively dry (i.e. does not become a puddle after rains). The

ground that the pond sits on must be level. I used some washed gravel that

I had on hand to make sure the pond base drained well, but this is not necessary

-- it can go right on the lawn.

Set a patio block or footing block to

support each of the 4 corners of the pond frame. Make these as level with

each other as possible.

The pond frame for the prototype is 4

ft by 8 ft outside dimensions. It is constructed with 2 by lumber. I

used mitered corners, however, and butt joint would work just as well. It

would be a good idea to use treated lumber for the boards that are in contact with

the ground.

The pond frame -- 16 inches high and

4 ft by 8 ft outside dimensions.

Make sure its level and square.

Check each of the edge boards with a

level.

Check for square by measuring the

diagonals -- when they are equal, the frame is square.

Make sure the grass or gravel

underneath is flat -- the bottom insulation board sits right on the ground.

The pipes from the solar heater to

the house need to be buried and insulated to prevent freezing, and to avoid high

heat loss.

Insulation Board:

The edge frame and the bottom are

lined with 2 inch polyisocyanurate (Atlas R-Board in this case). These

panels can be easily cut to size with a long blade razor knife.

Cutting the R-Board insulation panels

that are used to insulate the tank. It cuts nicely with either a saw or a

long blade razor knife.

Cutting the R-Board insulation panels

in the shop before fitting them into the frame.

I think that 2 inch thick

polyisocyanurate (Atlas R-Board is one brand) is a good choice. It has

high temperature resistance, and a high R value per inch. It costs about

the same as the pink and blue extruded polystyrene, but has better R value and

temperature resistance.

I used aluminum tape to seal the

edges better for moisture penetration.

The insulation boards being fitted

into the pond frame.

I used "Great Stuff" polyurethane

foam in a can to both glue the panels to the walls in a few places, and to seal

any gaps between the panels.

Liner:

The pond is lined with a single piece

of EPDM. Cut the piece to rough size. Remember that it for the

prototype it was about (41 + 14+14 +4 +4 + a bit more) = 80 inches

by (89 + 14 + 14 + 4 + 4 + a bit

more) = 127

Where 41 is the inside width, 14 is

the height, 4 is the thickness of the insulation board plus frame wall -- ad an

allowance to this just to be safe.

In my case I already had a piece of

EPDM that about 122 long, and I made this work by adding some wedge shaped

pieces of insulation board to the bottom corners .

You want the EPDM to extend all the

way to the outside of the frame boards, where it is attached

Cut the liner piece to size.

Mark the middle of each edge of the liner, and mark the middle of each edge of

the frame -- this makes it easier to install.

|

|

Using the middle marks to get the liner in the

right position. |

Install the liner -- clamp the middle

marks on the EPDM edges opposite the middle marks on the edge frames. Then

work the liner into the pond.

Work all the extra material into one

neat fold at each corner. Make sure that the liner is right up

against the insulation board everywhere -- you don't want it to be stretched

when the water is put in.

Once you get it to this point, you

can apply a bead of silicone between the liner and the frame, and then staple

the liner to the frame.

Note the two buried pipes coming up

next to the tank. These are the buried pipes to the house. After

everything is hooked up, this are will be boxed in with insulation (lots of it

where I live :) )

The pipe coil

For the prototype, I used two 100 ft

long coils of 1 inside diameter HDPE (High Density Polyethylene) that is NSF

approved. This is the commonly available black poly pipe that Home Centers

sell. Make sure it has the NSF label, as this assures that it is suitable

for drinking water. I used the lowest pressure rated pipe (100 psi) just

to see if this results in any problems, but I would recommend using the higher

pressure rated pipe.

One reason for using the two coils

is that it fits nicely into the pond. You don't have to fight with getting

it into a position it does not want to go into.

This shows the two coils laid out on

the floor and joined together. This is exactly the size coils they came

in. The right picture shows the short lengths of CPVC pipe to space

the pipe coils apart a bit for better heat transfer from the pond water to the

coils. I tied the coils with polypropylene twine.

The splice fitting that splices the

two coils together.

An alternative to the two 100 ft

coils would be to use one 300 ft coil. I believe that this would fit OK,

and it would hold somewhat more hot water in the pipe coil (12 gallons vs 8

gallons for the 200 ft). You would have to work out a way to spread

the coil out so that it occupies the full length of the pond -- its seems like

this might be doable. Remember that there must be a place for the pump

when you are done.

The Pipe Coil Connections

The pipe coil has to enter and exit

the pond. This means that they have to penetrate the pond liner. I

used two bulkhead fittings from our local AG store. I believe that

these are sold primarily to make connections through the walls of molded poly

tanks.

|

|

Back side of the bulkhead fittings. |

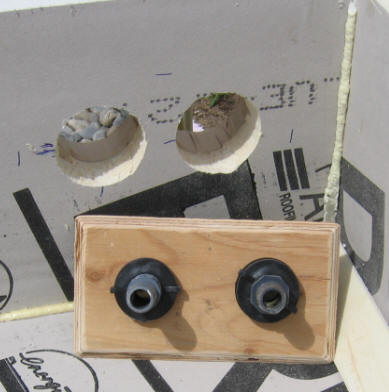

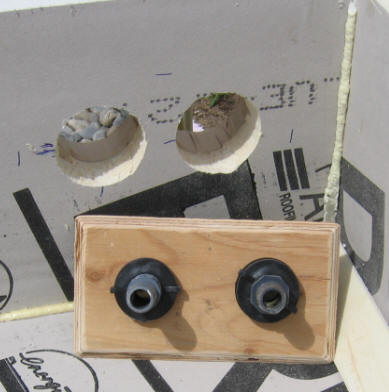

Shows the holes drilled in the pond

wall, the two bulkhead fittings (black), and the threaded to barbed adaptors

that adapt the poly pipe to the threaded bulkhead connectors. The

plywood goes behind the EPDM just to give the bulkhead fitting something

substantial to attach to, and to support the liner.

Coil Supports

The pipe coil should be spaced off

the bottom of the pond to allow for easier fluid convection around the coil, and

to place it in the hotter (top) part of the pond. I used concrete pavers

to space the coils off the bottom of the pond.

I put a few dabs of silicone on the

bottom of each paver just to keep it from abrading the lining.

I tied the coils down to the pavers

so that if the coils get a bit of air in them, the pavers will hold them down.

Note that the pavers will not hold down the coils if they are full of air,

so fill the coils with water before you fill the pond with water. I

drilled a hole in each paver to run the tie down string through, but this is

probably not necessary.

If you use something other than

pavers, be sure they will hold up to continuous exposure to hot water -- some

bricks won't.

This shows the coils placed in the

pond with the inlet and outlet routed to where the bulkhead fittings will be

installed. Right picture shows the bulkhead fittings installed, and ready

to hook up to the pipe coils.

At this point, hook up the pipe coil

to the bulkhead fittings and fill the pipe coil with water under pressure.

Check very carefully for leaks before you fill the pond with water. The

leaks will be a lot harder to spot after they are underwater :)

Pipe coil installed, and pond filled

with water. Make sure that the liner is not stretched anywhere.

The cover structure

The cover structure

The first prototype had horizontal

glazing. This was a bad choice for two reasons, 1) the glazing got very

dirty very quickly -- it actually sagged just enough to develop mud puddles, and

2) while the horizontal glazing collects a lot of sun the the summer when the

sun is high, it is poor in the winter with the low sun. Building a

sloped glazed structure over the pond with reflectors on the north, east and

west walls helps to solve both problems.

If I had it to do again, I would make

the slope even steeper in order to improve winter collection -- possibly sloping

the top of the back wall toward the south some to allow more low angle sun to be

reflected into the absorber.

The cover consists of a light wood

frame that is covered by wood soffit material.

The wood frame.

The south edge of the cover should be

as thin as practical to avoid shading the pond when the sun is low.

The pipe coil in the background was

used in prototype 2.

The cover assembly with the wood

soffit board material sides attached. The wood soffit board a pressed

board material sold in 4X8 sheets, and comes with what appears to be a very

durable outdoor finish.

I applied a thin layer of insulation

and then reflectorized Mylar to the inside surfaces of the cover.

This shows the corrugated SunTuf

polycarbonate glazing in place. This is available at Home Centers for $1

per sqft. In this picture, the intermediate glazing supports (every 2 ft)

are wood strips, I later changed these to half inch EMT conduit, which I think

works better and is more rigid.

The inner glazing frame is screwed to

the bottom of this cover.

The cover is hinged to the pond frame

so that it can be opened easily for access to the top of the absorber and the

pond.

Absorber and cover installed.

The EPDM absorber has not been trimmed or attached to the edge frame as yet.

The inner glazing panel

There is a layer of Mylar film

glazing just above the absorber. This layer provides added R value and

prevents water vapor from getting up into the cover assembly. The Mylar

and its frame are screwed to the bottom of the cover such that when you hinge

the cover up, the Mylar glazing goes up with it -- this gives direct access to

top of the absorber surface.

The Mylar glazing film is attached to

a simple wood frame, which is then screwed to the bottom of the cover assembly.

The Mylar glazing and frame.

The right picture shows the detail of the corner of the frame and attachment of

the Mylar to the frame. Use a bead of silicone caulk all the way around.

The Absorber/Lid and pump

(updated 7/8/07 to show the new

absorber/lid arrangement).

The absorber/pond lid is made from a

piece of 2 inch thick R-Board polyiso insulation, and then covered with an EPDM

cover, which acts as the absorber. When the sun is shinning, pond water is

pumped on top of the EPDM, heats up, and then drains back into the pond.

The insulated lid with its 2X4 frame.

The 2X4 frame sits directly on top of

the edge frame of the pond, and is screwed and sealed down to it.

The EPDM absorber goes over this lid.

The EPDM goes up over the edges of the 2X4s. The edges of the 2X4s extend

about 1 inch above the insulation board, and this is what makes the edges of the

shallow pond on top of the EPDM.

Corner joint.

The 2X4 edge frame is glued and

sealed to the 2 inch insulation board using Great Stuff polyurethane foam in a

can. You can just see little beads of it oozing out.

Bottom side is also sealed with

Silicone.

It might be a good idea to cover the

bottom with some form of water impervious layer that extends all the way out to

the outer edge of the 2X4s -- this would then give the water not access to any

of the insulation that surrounds the pond.

The lid has three penetrations.

-

The pump output line penetrates the

lid to move water from the pond to the top of the absorber.

-

There are two large drain pipes

that allow water that has been pumped on top the absorber to drain back into

the pond. These are set slightly above the level of the EPDM, so that

the pond has to be about a half inch deep before fluid can drain back.

This is to insure that the full lid is water covered. These are 1.5 inch

diameter PVC pipe siliconed into holes in the R Board.

This is one of the two drain

penetrations through the insulation board. The drain pipe is 1.5 inch PVC

(probably too big). I sealed the insulation board inside the hole with

Silicone, then pushed fitting through, and sealed a fillet around the fitting

with Silicone.

The drain fitting sticks up above the

top of the board so that a shallow pond will form on top of the board so that

the water pumped up from the pond reaches all parts of the absorber.

The drain fittings should be long

enough so that on the underside of the lid, they extend below the pond water

level.

I later added saw cuts in the two

drain fittings on the top side. The saw cuts extended down to the level of

the EPDM. The idea was that after the pump shut off, the water remaining

on top of the lid would slowly drain down into the pond. This has turned

out to not work very well, and some other solution is needed.

The pump pipe comes up from below

into this CPVC T fitting. It is sealed in the same way as the drain

fittings described above. About 10 inches of rubber hose connects the pump

outlet to this T fitting. The connection from the rubber pipe to the T is

just a tight friction fit.

The EPDM liner being fitted over the

insulation board lid. Some Silicone is used to bond the EPDM to the

Insulation board and 2X4 frame. The wood blocks are convincing the EPDM to

make a fairly square corner where it comes off the insulation board and goes the

one inch up to the top of the 2X4.

The hole being cut in the EPDM for

one of the drain fittings. The EPDM is just positioned over the drain

fitting, and a razor knife is used to cut the EPDM. Cut to the INSIDE of

the pipe, so that the EPDM must be pushed over the outside diameter and seals to

it well. Then seal with silicone.

Right picture shows the absorber and

insulation board lid ready to go.

The Attwood submersible bilge pump

mounted to the R-Board lid. The hose is a flexible rubber hose. Down

is to the left. I do not expect this pump to have a very long life.

Any ideas on a good 12 volt DC, low current, about 2 gpm pump, that is not too

expensive?

left Picture shows the absorber/lid

assembly ready to mount on top of the pond frame. The 2X4 frame of the

absorber/lid mounts directly on top of the pond edge frame, and over the EPDM

pond liner.

The right picture shows the

absorber/lid assembly mounted on the pond edge frame.

Water being pumped out of the T

fitting that connects to the outlet of the PV driven pump.

Wire and blue tape are for the pump

outlet temperature sensor.

The PV panel

The 15 watt PV panel is mounted at

the side of, and attached to the cover assembly.

The PV panel is supported by some

wood supports that screw into the cover side and back. This panel may be a

bit larger than needed, but I had it on hand. Its an about 15 watt panel.

Connections:

Right now, the water heater is not

connected to the house plumbing. I want to first run it for a while with

carefully metered water draws to get an accurate idea what the performance is.

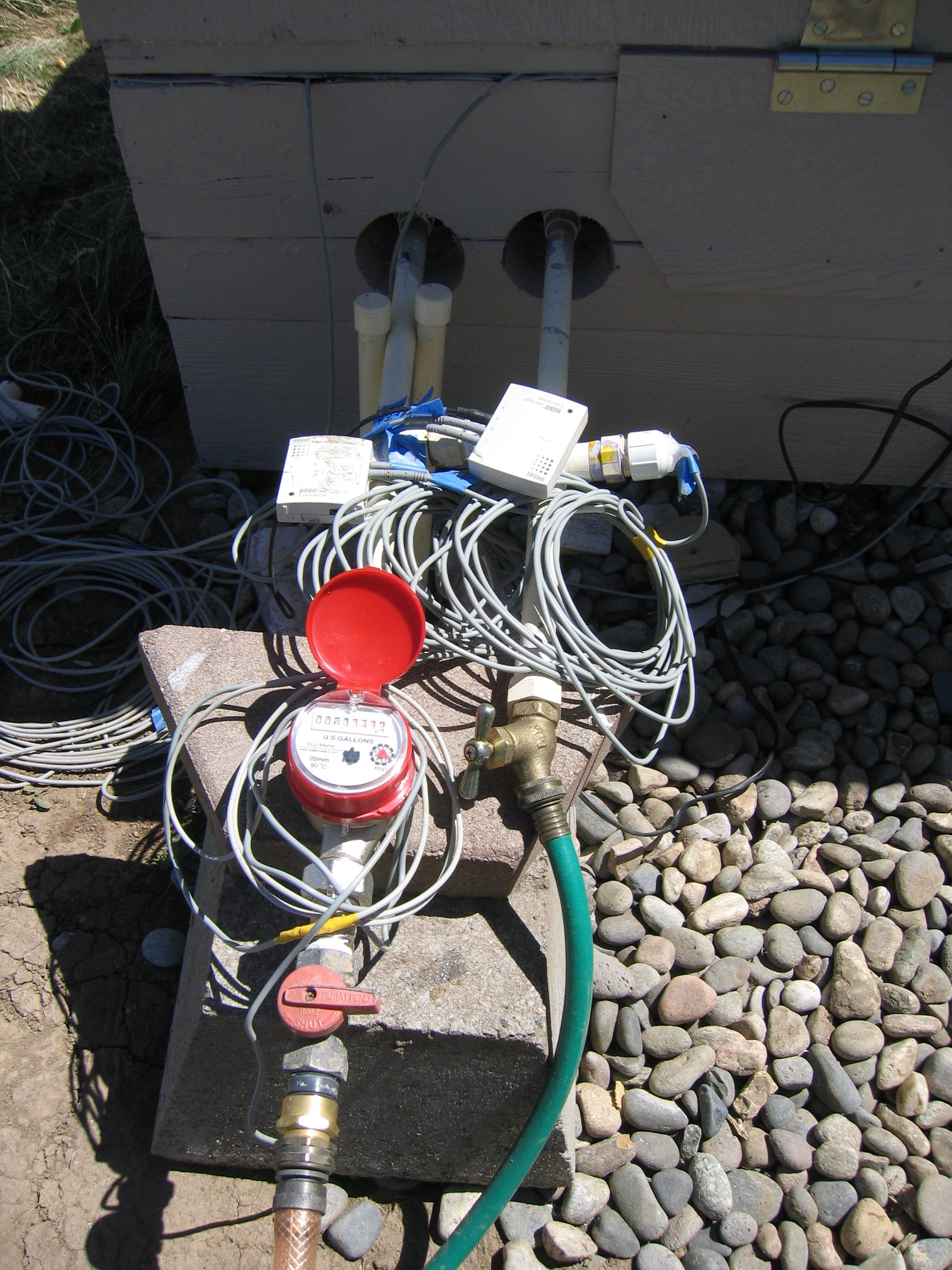

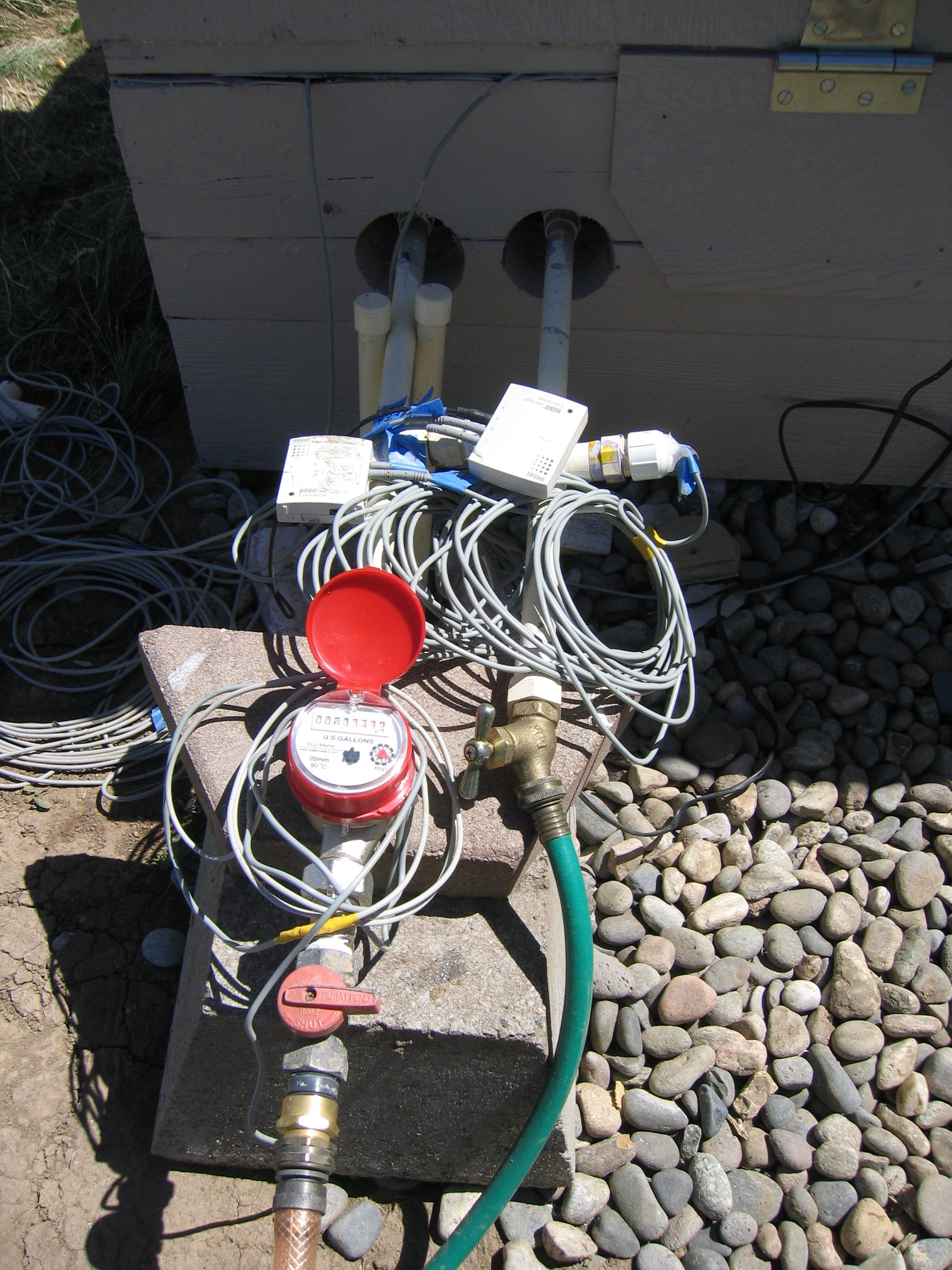

The current test setup. The

incoming cold water is the left connection with the red valve. This goes

through a water meter so that the size of water draws can be carefully

controlled.

The two white boxes are Onset

Computer data loggers. One logs the 1) pond temperature, 2) pump

outlet temperature, 3) absorber drain to tank temperature, and 4) solar

intensity (with an Apogee Pyranometer).

The second is used during draws, and

logs the pipe coil inlet and outlet temperatures and the pond temperature on 1

second intervals during the water draw.

Once the performance is better

understood, I'll hook up the pipe coil to the house plumbing and box in this

area with insulation. I believe that there will be enough heat loss along

the pipe from the pond to prevent any tendency to freeze when water is not used

for a long period of time.

Gary 6/25/07

revised 7/8/07