Search

The Renewable Energy site for Do-It-Yourselfers

Best Type of Black

Paint for Solar Collector Absorbers

There has been an interesting

discussion going on for the past few days in the Yahoo Solar Heat Group about

the best type of black paint to paint a solar collector absorber with.

Most absorbers are panted with flat black paint, but some arguments have been

made for glossy paint being a better choice --

see this Solar Heat thread for the details....

In the test described below,

I took some 6 inch square samples of thin aluminum and painted them with flat

and gloss paint. Then pointed them at the sun, and using surface mount

thermocouples stuck to the back of each panel, measured the temperature at the

center of the panel. Idea being that the panel with the highest

temperature is either absorbing more radiation or emitting less radiation (or

some combination of the two) is the best absorber paint candidate?

I also added a sample that

was painted with Thurmalox spray paint. This is a product intended for

painting collector absorber plates and is said to provide a somewhat selective

finish (ie a finish with high visible and near IR absorbency, but low emissivity

in the far IR).

Based on John C's suggestion,

the test was done for both near direct incidence, and also with the samples set

up with an azimuth angle of about 45 degrees to the sun.

I enclosed the samples in a

cover that was a good deal larger than the samples and that has a clear acrylic

front. The idea was to reduce the variability in the sample temperatures

that even very light breezes cause. This seems to have worked in that

successive readings were quite consistent.

The bottom line results (at

least for this test) is that the flat gives a consistently higher temperature:

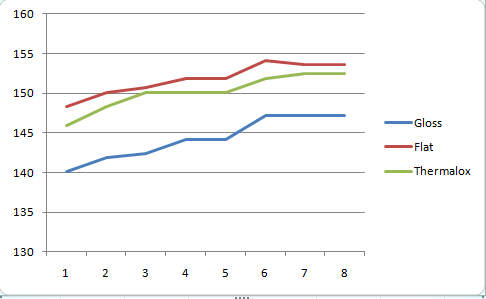

For near direct incidence

of sun on the 6 by 6 samples, the flat averaged about 7.3F hotter than the

gloss sample.

Flat average = 155.4F, gloss average = 148.15F

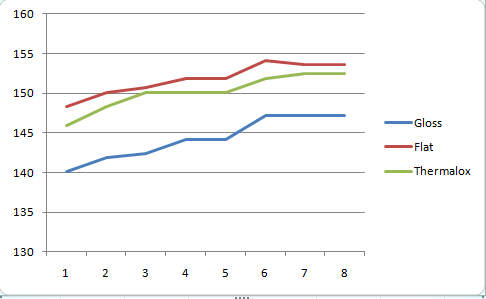

For the test with the sun

at an azimuth angle of about 45 degrees, the flat averaged abut 7.5 F hotter

than the gloss sample.

Flat average = 153.58F, gloss average = 147.13 F

The Thurmalox was

intermediate between the two -- perhaps closer to the flat

The paint thickness measured in one

place on each sample (it no doubt varies over the sample):

Gloss - 0.7 mil

Flat -

0.6 mil

Thurmalox - 0.6 mil

In all cases, the paint appeared to

provide a fully opaque coating. My aim in the painting was to apply the

thinnest coating possible that was fully opaque.

I'd be interested to hear what people

conclude from this, but my tentative conclusion is that I'll probably stick with

using the Rust Oleum flat black high temperature BBQ paint.

Just as a side issue, the flat black

paint also seemed to provide better adhesion -- I noticed this while removing

the paint from a small patch on each sample to measure the thickness.

I'm not quite sure what to make of

the Thurmalox results -- I had expected it to have the highest temperatures.

I may have applied it in to thick a coat to get the beneficial effects. I

have done a small panel test with the Thurmalox -- in that test, it appeared to

just a touch better than flat black paint, but the difference was not great.

Direct incidence test

|

Sun at 45 degree azimuth test

|

These pictures show the test

setup:

If you see anything that

looks wrong, please let me know.

Samples from left to right

are Thurmalox, flat black spray paint, gloss enamel spray paint.

The three paints.

The cover is intentionally

leaky to allow a little air circulation, but to keep any light breezes away from

the samples.

This picture from the previous day

test shows how the surface mount thermocouples are stuck to the back of the

samples.

The thermocouples come into the TC

switch at the left, and the temperature values are read by the Onset Computer

logger (little white) box, and then read on the little laptop. The switch

is needed because the logger only reads one thermochouple input at a time.

So, readings were taken by switching

to each thermocouple in succession -- cycling through all three takes about 10

seconds. The cycle was repeated about 10 times to insure consistency.

While the average temperatures drifted up a bit during the test, the differences

between flat and gloss were quite consistent.

The samples and enclosure rotated to

produce an about 45 degree sun azimuth angle.

Air temperature inside the enclosure

was about 93F. Ambient temp started at 60 F and was rising during the test

period.

The sky was nearly clear with some

high, thin, wispy clouds.

The Test Spreadsheet Results

|

Comparison of absorber paints |

|

|

|

|

|

|

|

|

|

|

|

27-Sep-10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Gloss = Rust-Oleum Gloss Protective Enamel 7779 Gloss Black |

|

|

|

|

|

|

|

|

Flat = Rust-Oleum Flat Protective Enamel 7776 Flat Black |

|

|

|

|

|

|

|

|

Thurmalox = Thurmalox Solar Collector Coating 250 Selective Black |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

Weather was quite clear with some very thin lacey widely dispersed

clouds, Tamb 60F at start |

|

|

|

|

|

Air temperature in enclosure was 90F near end of test. |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

Near direct incidence test |

|

|

|

| |

Gloss |

Flat |

Thurmalox |

|

10:10 AM |

145.36 |

153 |

148.89 |

|

| |

145.95 |

152.4 |

149.47 |

|

| |

145.95 |

153 |

150 |

|

| |

146.54 |

152.4 |

150.06 |

|

| |

146.54 |

153.58 |

150.16 |

|

| |

147.13 |

154.17 |

151.24 |

|

| |

148.3 |

154.76 |

153 |

|

| |

148.3 |

155.93 |

153.8 |

|

| |

150.06 |

158.28 |

151.82 |

|

|

10:18 AM |

151.06 |

158.86 |

155.93 |

|

| |

151.24 |

158.86 |

156.52 |

|

| |

151.41 |

160.04 |

157.1 |

|

| |

|

|

|

|

|

45 degree azimuth test |

|

|

|

| |

Gloss |

Flat |

Thurmalox |

|

10:22 |

140.07 |

148.3 |

145.95 |

|

| |

141.84 |

150.06 |

148.3 |

|

| |

142.42 |

150.65 |

150.06 |

|

| |

144.19 |

151.82 |

150.06 |

|

| |

144.19 |

151.82 |

150.06 |

|

|

10:28 AM |

147.13 |

154.17 |

151.82 |

|

| |

147.13 |

153.58 |

152.41 |

|

| |

147.13 |

153.58 |

152.41 |

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

Gary

September 27, 2010