Search

The Renewable Energy site for Do-It-Yourselfers

Title ..

A good design for a DIY pool heating collector is to use thin wall 1/2 pvc

with 3" header pipe. Basically mimicking a commercial pool collector.

So header maybe 20 ft long, and length of the riser can be as long as you

wanted. Space really close together.

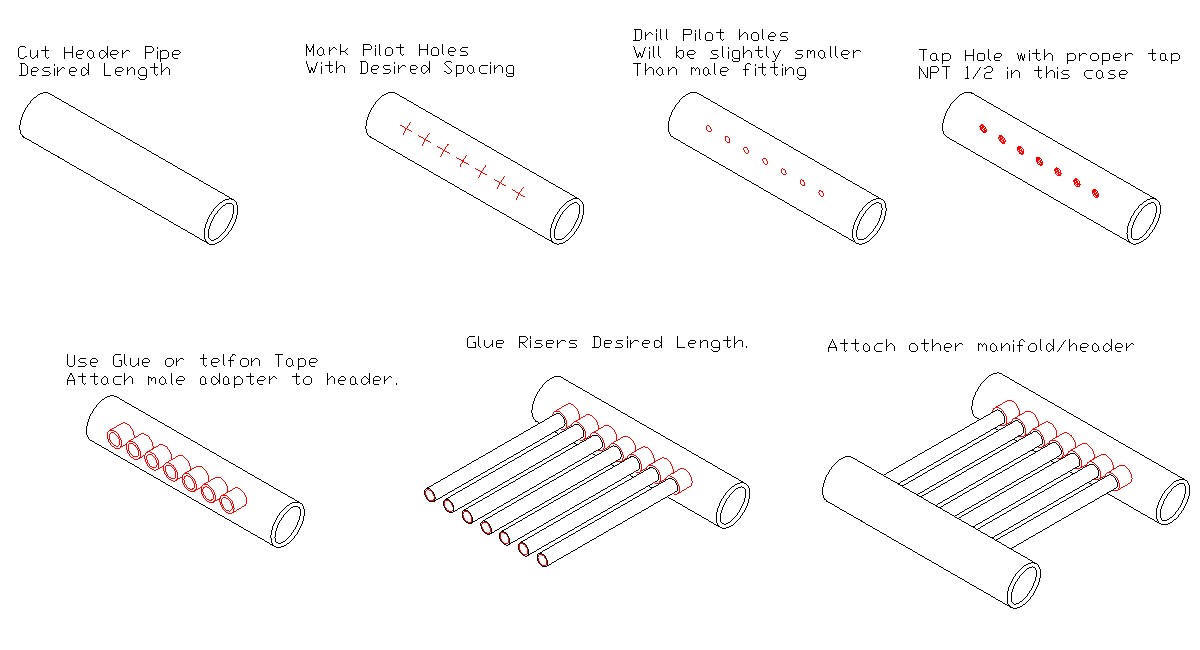

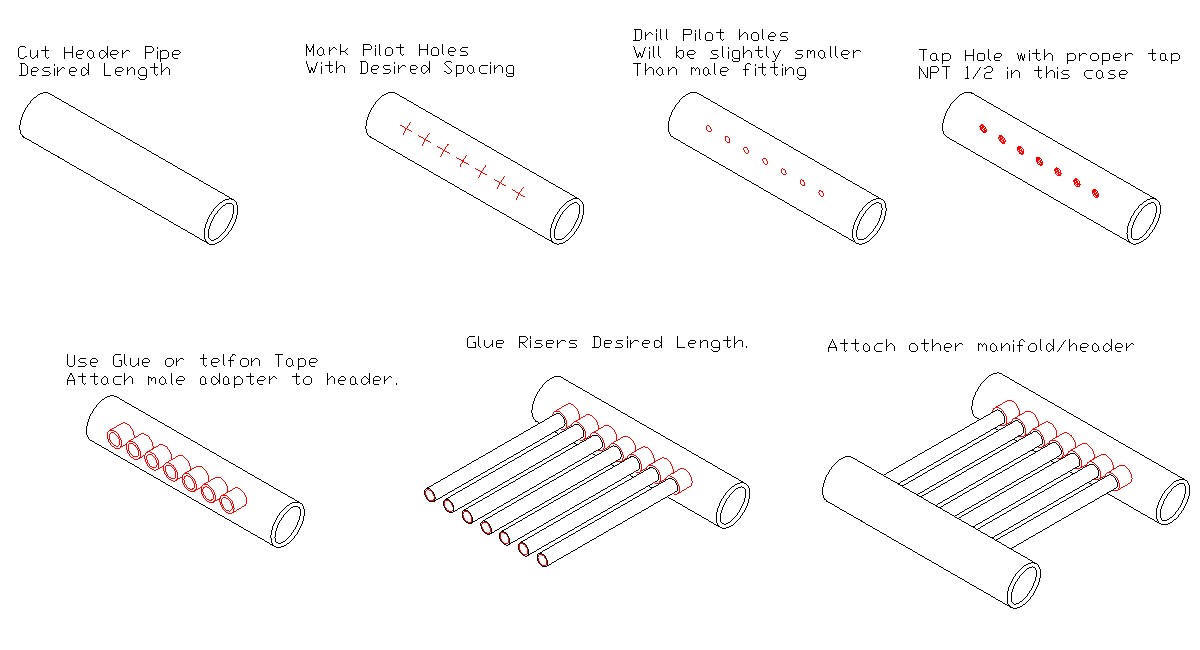

What you do is take you 3 inch header pipe. You drill pilot holes where the

thin walled pvc will connect to. Next you take a tap(about $10 and found pretty

much anywhere in the world)

You make treads where you previously made pilot holes. You do this for the

entire header. You now take threaded fittings and you either apply glue on

threads or use teflon tape. You connect the threaded fitting to the large

header(manifold). You do this for both manifolds. Next you glue the 1/2" pvc

lengths to the manifold.

This will leave you a collector that is highly parallelized and VERY LITTLE

pressure drop, and rectangular in nature so it uses space better. I post this

here mainly for other people at this point. After everything is done use spray

paint to paint the pvc. I made a roughly 12sq meter(120sqft) hot tub collector

that worked surprisingly well.

A panel that is 10 ft wide would have roughly 75 risers. 75 risers at maybe 40

ft long each. Each riser would have less than .833 gpm. based on 62.5 gallons

per minute total

Using same calculator I get a pressure drop of roughly .4 psi in any riser,

and the header(manifold) would have very minimal as it would be a 3 inch pipe.

The reason to use a 3 inch pipe is so that when you are making a threaded hole

the hole lands fairly flat on the pipe. I also used schedule 80 pvc for the

header to allow the threaded holes to be deeper. Schedule 80 costs a bit more

money but really there is minimal amounts of that. There is tons of thin walled

1/2" pvc. But Should run similar costs to irrigation tubing. Apart from making

the headers it would save alot of time and could even be a one man job.

I can verify the pressure drop as I installed pressure gauges on the system I

installed. I was amazed at how little pressure was added to the system.

Back to your system. To me even 13.1 psi is high. In the pools I have been

involved in we used 2" pvc which is fairly good I would have rather gone 3" but

we did not use a single 90 degree fitting, and we only used tees of the jets in

the pool.

We used more expensive Y fittings heated and did alot of pvc bending, and

bought very large filters(about 100% oversized compared to "experts") to reduce

pressure drop. And pump house was right next to the pool to limit pipe runs.

Although the houses were off grid.

point being if you can split to 28 loops 500ft each and only send 1gpm per

coil. You could get down to 2.8 psi drop. I would think you would save a good

bit of pump energy and still have a good out come.

Someone may want to check my math.

Matthew