Search

The Renewable Energy site for Do-It-Yourselfers

Solar

Horse Tank -- Version 2

Livestock watering tanks will

develop a layer of ice in cold weather, and then progress into a solid

block of ice if not tended to. The usual solution for this is to

use an electric stock tank heater. These are thermostatically

controlled heaters that turn on when the stock tank water gets near

freezing. The heaters do a good job of preventing ice, but they are terrible power hogs.

|

Typical stock tanks have a

large exposed water surface that loses heat by both convection and

evaporation. They also have highly conductive

single wall sides and bottom that are in direct contact with cold air or

cold ground. If you set out to design a tank to maximize heat

loss, you could not do much better than a typical galvanized or plastic

stock tank -- they are awful. The result is lots of energy

consumption, high electric bills, and high CO2 emissions.

|

NEW

Our Solar Stock Tank featured in the October issue of Mother

Earth News...

|

We measured the electricity consumption of the heater on

the old tank during

mild winter weather at 8.5 KWH per night -- this is with night lows in

the 15F to 30F area, and highs in the 25F to 40F area. I would

guess that with "real" winter weather you could see 30 KWH per day

-- this will cost $3 a day and generate 45 lbs of CO2 a day.

The material below describes

the latest version in a series of insulated and solar heated

stock watering tanks that require little or no supplemental heat to be

free of ice. Complete construction details are included.

|

|

History leading to the tank design

The table below shows the original

prototype and several follow-on designs built by Build It Solar readers. They

all work well, and in reviewing them you may find ideas in that will fit your

situation.

Here are some

other schemes (both commercial and

homemade) that are being used to minimize ice problems ...

Our New Tank

This design is based on the ideas

and lessons from the all of the above designs, and from Lori's (my neighbor with

horses) ideas on horses and their interesting habits.

The changes from the prototype

include:

-

Using a galvanized stock tank

as the base

A lot of people already have these, they are durable and not to

expensive, and the metal wall painted black on the outside makes a good

solar absorber. They seemed to work out well for Steven and CS in their

tanks.

-

Double glazing

I used two layers of the SunTuf polycarbonate glazing for the south wall

of the enclosure in front of the absorber.

This should about cut the night time heat loss in half, while only cutting the

solar gain by about 10%.

-

Nice simple framework

The rectangular 2X4 framed plywood covered box is easy to build and easy

to install insulation in.

-

Lid over tank with horse head

size opening for drinking.

The lid over the tank helps to cut down the heat loss from the open

water.

The idea of a floating insulation lid was not tried, as it was thought

to be to susceptible to damage.

The water surface is still a high heat loss area, and while the

partial cover helps, I'm sure that performance could be improved if the

top water surface could be better insulated. Any ideas?

I think that the end result is easy

to build, durable, and will handle the ice problem without supplemental heat in

all but the most extreme weather.

Performance

We measured the consumption of the

electric heater on the old tank (a bare galvanized tank) during mild winter

weather at 8.5 KWH per full day -- this is with night lows in the 15F to 30F

area, and highs in the 25F to 40F area. I would guess that with "real"

winter weather you would see 30 KWH per day -- this would cost about $3 per day

and result in about 50 lbs of CO2 emissions.

Lori's experience with the new tank

so far is that it is fine with no heater almost all the time. On

cold mornings there may be a very light skim layer of ice that is easily broken

with a small push from a finger. If you do get this ice in the morning, it

usually goes away completely later in the day.

There have been a couple of occasions

over the full winter when several days of -10F or worse type temperatures required

the use of the heater for a couple days. Even in these circumstances, the

insulated tank greatly reduces the heaters electricity use.

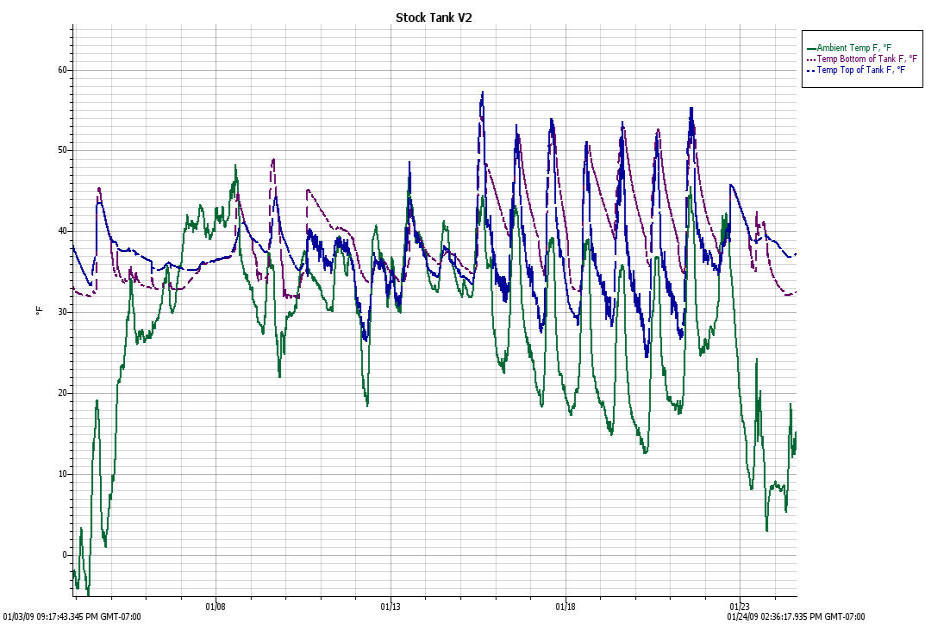

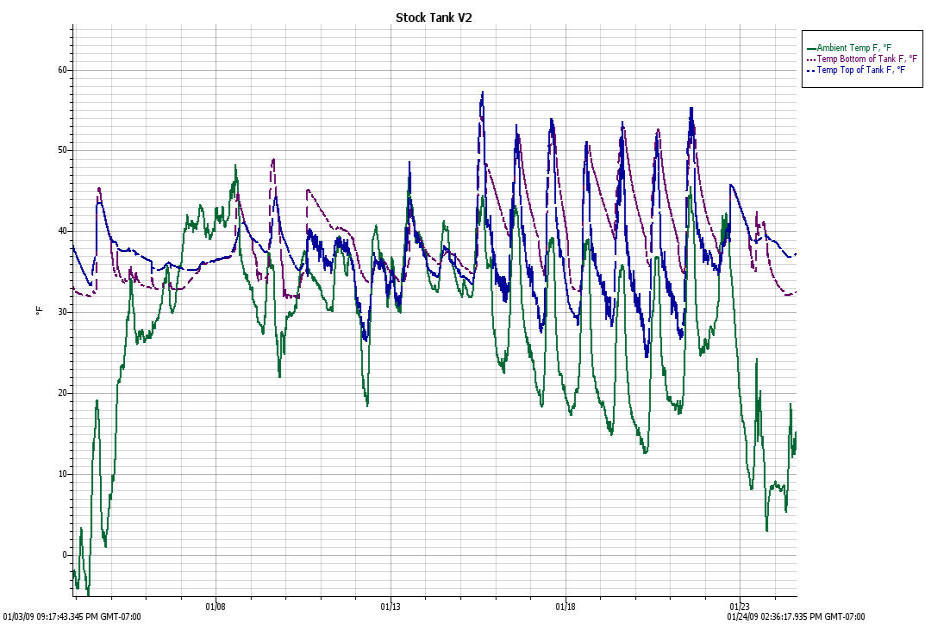

This is a sample plot for a few days

showing ambient temperature, and the temperature near the top of tank and near

the bottom of tank.

Customer Acceptance

The horses seemed to take the new

tank in stride with no problems. Lori thought they might have a problem

sticking their heads into the fairly small opening, but they took to it with no

problems.

Lori, Princess and Darby

Construction

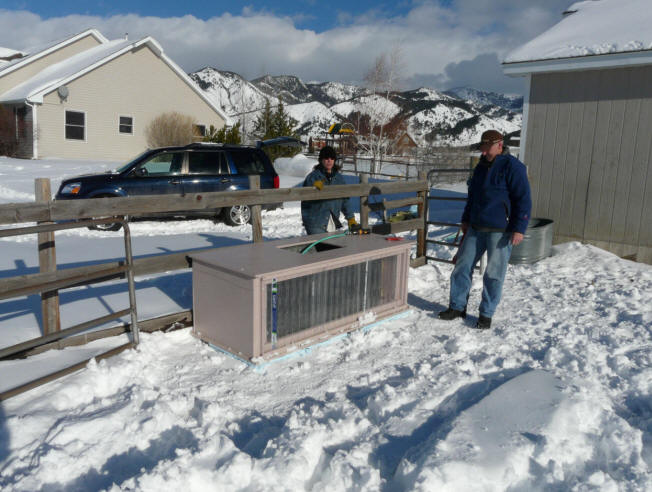

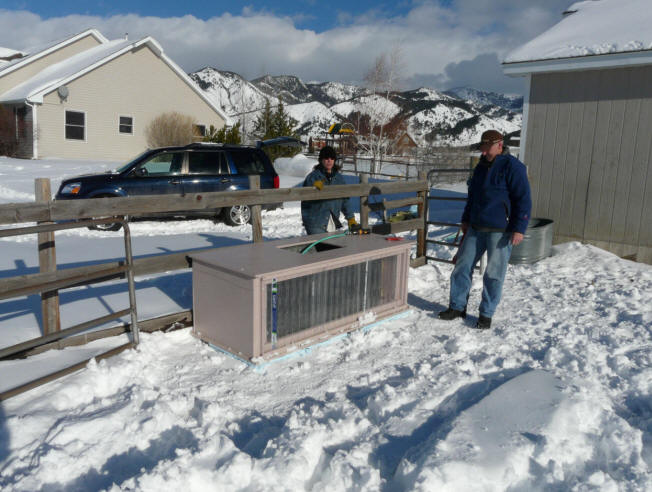

The pictures just below provide an

overview of the tank construction.

Go here for much more step-by-step detail on the tank

construction ...

1 - Build the frame for the

insulated box that encloses the tank

|

The box that encloses galvanized stock tank is framed

with 2X4's. |

2 - Cut and attach the plywood sides

to the box

|

Cut out and attach the plywood sides and back of the

box. The front is left open for the collector glazing. |

3 - Cut and fit the Top and Bottom

of the box

|

Cut out the top and bottom panels for the tank. The

bottom is installed at this time, and the top set aside to be installed

as the last step.

The top has the hole to allow the horses access to the water. |

4 - Paint and seal the box

|

All of the box enclosure parts need to be protected

with exterior paint. All the seams should be caulked to reduce air

infiltration. |

5 - Install insulation board

|

The insulation board is cut out and fitted to the

bottom and sides of the tank. |

6 - Install the glazing

|

The two layers of SunTuf polycarbonate glazing are

fitted to the front opening of the box. SunTuf is a highly transparent

and very tough polycarbonate glazing. |

7 - Install the galvanized tank and

the cover

|

Place the galvanized tank in the box. Add the cover.

Add water.

|

First fill.

Go here for much more step-by-step detail on the tank

construction ...

Potential Design Improvements

The tank is doing quite well in its

current incarnation, but there are always things that might be improved -- here

are some candidate design improvements.

Glazing Protection:

While

Lori's horses don't seem to be interested in damaging the SunTuf glazing, and

the polycarbonate is pretty tough, you might want to consider protecting the

glazing if you think your stock are likely to damage it. The hog panels

that CS used on his tank seem like a good way to go.

Draining:

The tank is difficult

to drain. I plan to add a drain pipe and valve that goes through an

insulated hole in the outer enclosure and connects to the threaded drain plug on

the stock tank.

Better Lid:

A lid design that

allowed the tank water surface to be better protected from exposure to cold, and

is stock proof would be a good improvement. This is the only major

remaining heat loss, and reducing it would probably eliminate the need for any

supplemental heat even under extreme conditions.

Update: September, 2, 2013

This appears to be a good improment on the lid design that reduces heat losses and is simple to do...

Rachel also reports that she covers the drinking openings at night and then takes the covers off in the morning. This should be a very good reduction in heat loss fromt the drinking hole.

Insulation Levels:

The 2 layers of thick foam board insulation

on the bottom, sides, and back may be overkill.

The R value on the bottom,

sides, and back with 4 inches of extruded polystyrene is about R20.

The heat loss with an outside temperature of (say) 10F, and a water temperature

of 40F is about (42 sqft)(40F - 10F)/ (R20) = 63 BTU/hr or 1500

BTU/day.

The 1500 BTU/day heat loss would cool

50 gallons of water by (1500 BTU/day) / ((50 gal)(8.3 lb/gal)(1 BTU/lb-F))

= 4 F a day from heat loss through the bottom and sides.

The heat loss through the front out

the double glazing is about (10 sqft)(40F - 10F) / (R2) = 150 BTU/hr

or 3600

BTU/day -- so the heat loss out the front double glazing is twice

that of the heat loss out the back and sides. The heat loss from the top is hard to

calculate, but is probably at least as much as the front. This probably argues that

the insulation on the back and sides could be cut back some without effecting

the performance of the tank a lot.

So, if you wanted to cut the budget a

bit for building the tank, I think it would still perform quite well with one

layer of 2 inch extruded polystyrene all the way around. Be sure that all

of the 2X4 frame gets some insulation on the inside -- don't let the 2X4's

bridge heat into the box. Another way to save some money on insulation

would be to use rigid foam board under the tank but use fiberglass insulation

around the sides and back.

Note that if the heat loss out the

glazing seems like a high price to pay for the solar gain, the gain for just 1

hour of good sun makes up for the heat loss through the glazing for a full day.

Insulating Covers:

If you visit the tank location fairly often,

the overnight heat loss could be cut drastically by: 1) placing an insulated cover

over the drinking opening at night, and 2) placing an insulated cover over the collector

glazing at night. This could be done when very very cold nights are

anticipated. Even doing just the insulated cover over the drinking

opening would probably help quite a bit. Do horses drink at night?

In Shaded Areas, Eliminate the Solar

Collector:

If the location for the tank gets

little or no sun, then just use insulation all the way around the tank.

This should still reduce the ice formation problem significantly. The

water has a lot of thermal mass, and has to be cooled from around 50F down to

32F for ice to start forming. If the heat loss rate is reduced by using

insulation, it will take some time for the water to cool enough to form

significant ice.

Use the tank with a heater:

Note that the tank could be used with

an electric stock tank heater in extreme cold weather. The added

insulation should greatly reduce the power consumption of the heater. If you think you might want to

be able to use an electric heater, then allow for the heater cord in the construction.

Wow! -- carrots

Gary & Lori March 15, 2009