Search

The Renewable Energy site for Do-It-Yourselfers

Tom's Wind Turbine

-- Tower Raising

System

Tower Raising System

I had thought about the logistics of raising a tower this big, and had 10 ton

winch from a truck laying around at my dealership. The problem I had was that I

had not figured out a way to drive the winch. In it's earlier life it was driven

by a PTO (power take off) on the truck. I wanted the ability to raise and lower

this without a lot of outside help, so finding a drive

mechanism to this winch made the most sense. I also was concerned about the

total weight we would be lifting through the gin pole. I didn't know a way to

calculate this, so built a scale model in my garage and attached weights and

cables to determine the load factors. I found my particular tower was at 4 to 1

(tower weight horizontal to gin pole weight required to lift it). With a 4,000

lb. tower, I needed 16,000 lbs. of pull to right it.

With that fact known, I needed to firm up the final design of the winch system.

I spent some time, doing calculations based on distance and weight of the lift,

and found 3 HP would raise the tower in 10 minutes. Less HP would take longer,

substantially more HP would be quicker but expensive. We found the 8 HP Briggs

running my cement mixer was the perfect fit. It was totally self contained, and

only needed 4 bolts removed to take it off the mixer. We installed the winch on

a 1" plate and fabricated mounts for the Briggs to drive a 5/8" belt to the

winch. The proper pulleys (or sheaves as some call them) were ordered based on

the ratios worked out for a 10 minute lift. I decided to give the old 8 HP

engine (and my math) a little leeway. Part of the winch speed reduction was also

a set of snatch blocks installed between the winch and the gin pole. We reduced

the speed by a factor of 3, and increased the power by the same amount.

The gin pole installation posed a challenge. How would we stand this trussed

pole up to install it when it is 55' long? After careful thought, I realized an

early design flaw was limiting our ability to install the gin pole easily. Our

limitation was the "swing area" of the base of the pole at the hinge point. By

extending the hinge point farther from the main tower, the gin pole could be

installed at a 180 angle to the tower. In a "laying down" position, the gin pole

installation was a snap. One concern I had once installing the 55' gin pole was

the possibility the pole would "break out" the pivot pin or mount, trying to

give way under the 20,000 initial lift. I knew the truss would support the pole

from collapsing, but 55' is a lot of leverage on the hinge point. Looking at the

tower anchor points, I realized guide cables on the gin pole would be easy to

add. With a little more torch work and welding, we had anchor points to install

guide cable on the gin pole much like we did on the tower. A little apprehension

was starting to go away.

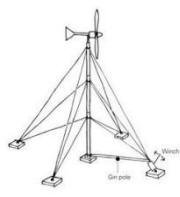

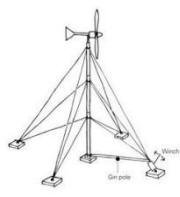

Note: these two

diagrams of a much smaller tower illustrate the how the main tower is raised

using a gin pole.

|

Tower fully raised. |

Tower being raised with a gin pole. |

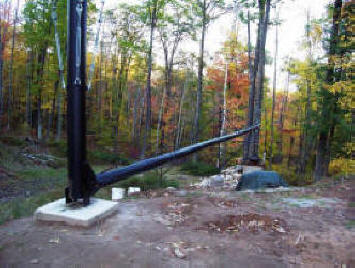

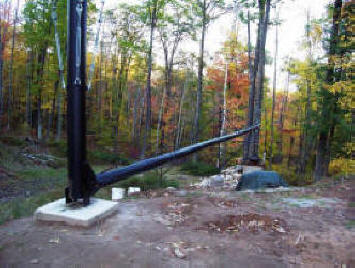

Tom's tower raising --

Click on pictures for full size

|

Gin pole winch driven by gas engine. |

Main pole to gin pole connection -- winch in distance. |

|

An extra set of pulleys increased winch force. |

Winching station and elevated footing. |

|

Tower guy anchors and fittings. |

|

At this time all the guide cables were assembled and tensioned. The Prairie

Turbines design calls for one set or four 5/8" guide cables. With the extra

height, we elected to use two sets of four. The tops cables are attached just

above 120' on the tower, and the lower ones are about 80' up. We installed an

extra 3/4" cable from the gin pole to the tower at 100' due

to the excess stress we would see during the raise of the tower. At 20,000 lbs.

we would exceed the working load of the two 5/8" cables during the start of the

tower lift. We used a log truck with a knuckle boom loader to raise the gin

pole, letting out winch cable as we raised it. All remaining guide cables were

installed, and the side cables were tensioned for the lift. It took a few tries

to get the "gin pole to tower" cable lengths correct. Some miscalculation was

evident, as we had to use chains to lengthen the two 5/8" cables until I could

get more cable hardware to properly size them. When tensioning the "gin pole to

tower" guide cables with the winch, the tower started raising very easily. It

was evident the system will work.

Note:

More information from OtherPower on another gin pole style tower...

First Tower Raising

On October 1st, 2008 the tower was

lifted.

We got a surprise when hoisting it the first time, finding that the weight of

the gin pole overcomes the weight of the tower at about 85 degrees. It free fell

to vertical the first time (the last 20'). Thank god the guide cables opposite

the gin pole held. I am developing a counter measure for the next lift to

accommodate that problem. Obviously I will need something to help get it to 85

degrees when lowering anyway.

Gin pole -- ready to raise main tower.

This sequence shows the tower being

raised for the first time -- click on pictures for full size.

Tower fully raised. Note the clearance to the surrounding trees.

October 19, 2008