Search

The Renewable Energy site for Do-It-Yourselfers

DIY Solar Collector:

Optimizing the Thermal Conductivity of the Fin to Riser Tube Joint

I've received a some

emails wondering if the silicone caulk used between the

aluminum fins

and copper or PEX tubing is really a thermal benefit, and suggesting

that perhaps the silicone isolates or insulates the riser pipe from the

aluminum fin, and may do more more harm than good. Others

have have suggested that something other than silicone caulk with

greater thermal conductance might work better to fill the gap between

the aluminum fin and the riser tubes. I've done some thinking,

testing, and calculating on this issue, and the raft of stuff below goes

over all this. My thanks to all the people who made these

suggestions!

From my knothole, the bottom

line is that the silicone caulk remains a good choice because it shows good

thermal performance and has several other very desirable

characteristics. And, that any thermal improvement

resulting from substituting a more conductive material would likely be small. But, please read the material below, and see if

you agree -- or maybe have another approach to suggest?

If you are

wondering

what in the world this is all about ... |

|

The current reasoning for using

silicone caulk between the fins and tubing

The reasons I've included the

silicone caulk between the fin and tube on collectors built to date are:

-

The silicone caulk fills any

small gaps between the aluminum fin and the tube that would otherwise be filled with

air. The silicone has a

thermal conductance around 0.25 w/m-C and air has a thermal conductance around 0.025

w/m-C -- so the silicone is ten times more conductive than air, and I

believe that this results in better performance. The

small panel tests comparing air in the gap vs silicone caulk in the gap (see

below) tend

to support this. The calculation of the thermal resistance of a very

small gap filled with air or filled with silicone caulk (below) also tend

to support the idea that 1) the gap filled with silicone will have better

thermal performance, and 2) that the thermal benefit of a more conductive

material than silicone caulk will not be large. The one caveat here is

that the amount of silicone must not be excessive, and must not result in a

larger gap because any excess silicone is not squeezed out -- This is

discussed below, but I don't thing that

its a problem in practice.

-

When you staple the grooved

aluminum fin over the tube very tightly, you should get a very small gap to

no gap between the fin and the tube. The silicone caulk is a

good adhesive, and will tend to keep this small to no gap condition for the

life of the collector. It basically glues everything into place and

keeps it there. If you don't put the silicone in, the thermal

expansion and contraction may work the staples over time and may allow a

larger gap to develop between the fin and tube over time -- mind you, I

don't know that this would happen, and it may not.

-

Silicone caulk is a very good

material to use in collectors -- it has a long track record of standing up

to the very difficult environment inside of collectors for a very long time

without degradation. Many materials don't do well inside of

collectors.

-

Silicone caulk remains

flexible after curing, so it can handle the differential thermal expansion

between the fin and tubing.

-

Silicone caulk acts as a barrier

to prevent galvanic corrosion between the aluminum fin and the copper pipe

-- it prevents the entry of water from condensation into the area between

the fin and the tube and it physically separates and protects the aluminum

and the copper. It adds to the protection offered by the paint finish.

-

Silicone caulk is cheap,

safe, and readily available.

This sounds a bit much like a

commercial for silicone caulk, but (honest) I don't sell it make it. I do

think we are lucky to have such a good material for use in collectors, and that

it is cheap and easy to find.

Looking at the Suggestions for

Improvement

The suggestions for improvement

include:

-

Leave out the silicone caulk on

the idea that it does more harm than good. An offshoot of this is that

the silicone caulk may result in a larger gap between the fin and tube if it

is not well squeezed out.

-

Use a thermal grease or heat sink

compound that has a higher thermal conductivity than silicone caulk.

-

Us a silicone caulk that has been

formulated for high thermal conductivity. There are some specialty

silicone caulks that use fillers to achieve higher thermal conductivity.

On item 1, I don't see the merit of

this. The test and the calculation below both indicate that a silicone

caulk filled gap will have significantly better thermal performance than an air

filled gap. The test panel and calculation indicate an about 2 to 6%

improvement in heat output for collectors with a silicone filled gap over an air

gap.

Based on some informal testing and

sectioning of one of the test panels, I don't believe that the silicone results

in a thicker gap as long as you take some care in the assembly. This is

basically because the excess silicone can be squeezed into the area between the

grooved fin and the flat aluminum base plate -- that is, the excess silicone

does not have to travel to the ends of the fin groove.

On item 2, I am leery of using a

non-curing thermal grease or heat sink compound. I don't think that these

materials would glue the fin and tube together as the silicone caulk does, and I

think that having the fin and tube glued together is important to prevent the

gap between the fin and tube from increasing over time as the collector is

worked by thermal expansion and contraction (of course, I may be totally wrong

about this :) In any case, the calculation says that the gain in

collector efficiency for using a more thermally conductive material would be

small.

On Item 3, I do think there would be

a small gain (see calculation below) if one could find and obtain a high thermal

conductivity silicone caulk. I've asked for a sample of CHO-THERM

1641, which is such a caulk, and will test it if the sample comes through.

Based on the calculation below, I would not expect to see a large improvement in

performance, but I'd like to see how the test comes out. If anyone has a

good source for a high thermal conductance silicone caulk, please let me know.

Update: May 2011 --

here is result of testing a high thermal conductivity silicone ...

Small Panel Test -- Silicone in Gap

vs Air Gap

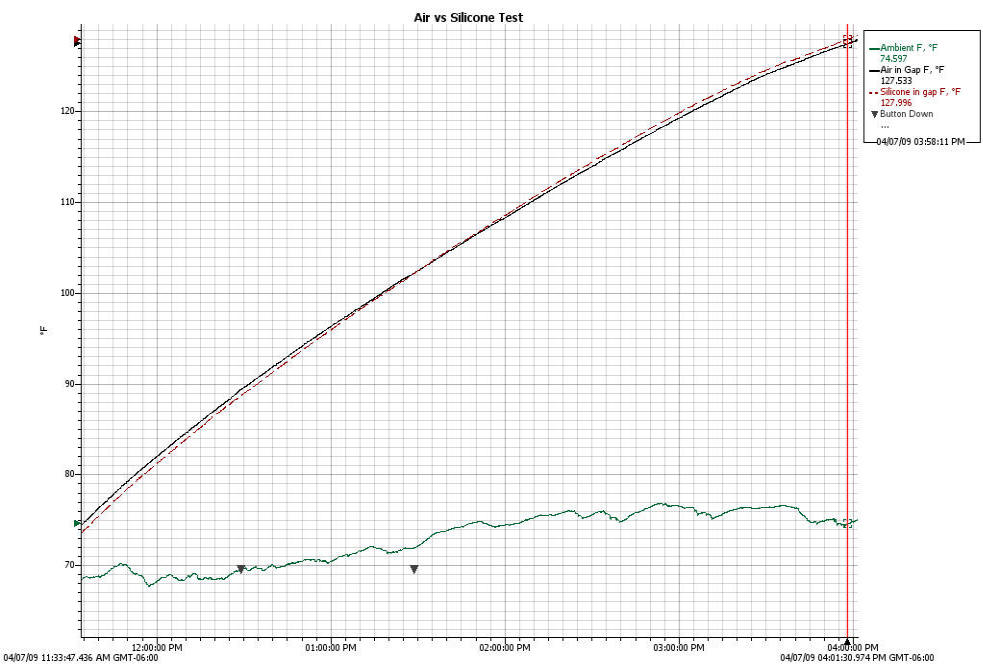

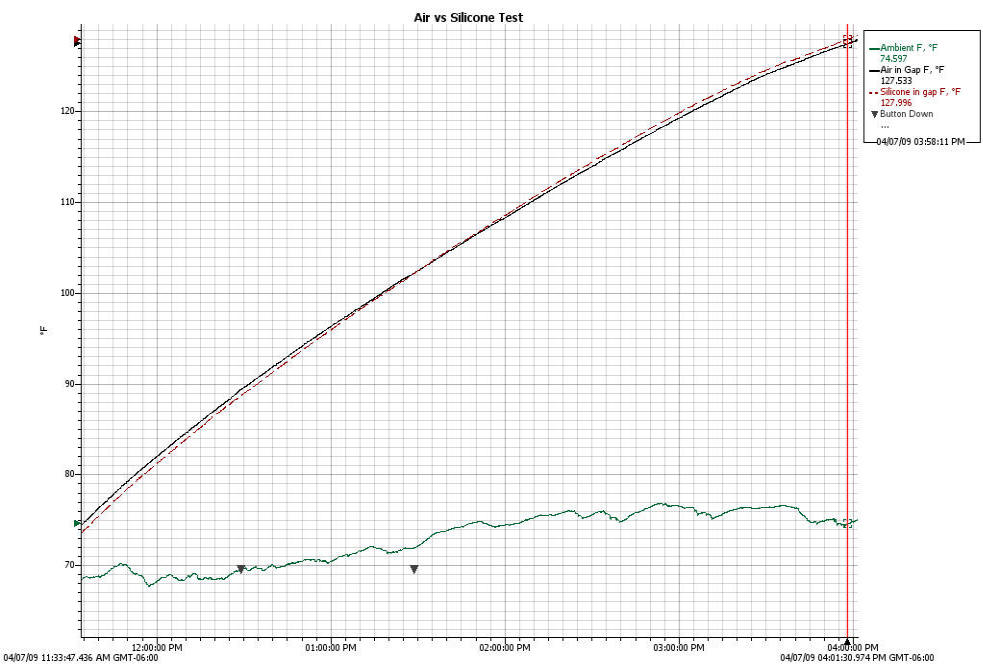

The aim of this test is to compare

the performance of a collector with silicone caulk in the gap between the fin

and the riser tube to one with air in the gap.

Click on pictures for full size

|

The two test panels and reservoirs

during the test. |

Closeup of panels -- same size

and orientation. |

One of the test collectors

before adding the glazing. |

Test Setup:

Red line -- reservoir temperature

for the panel with the silicone filled gap

Solid black line -- reservoir

temperature for the panel with the air filled gap

Green line -- ambient

temperature.

Both reservoirs filled with 29

lbs of water.

Absorber area for both collectors

is 2 sqft.

Glazing is SunTuf corrugated

polycarbonate.

Back insulation is 2 inches

polyisocyanurate foam board.

Reservoir temperatures are logged

with an Onset Computer U12 logger using 10K thermistor temperature sensors

immersed in the reservoirs at the pump inlets.

Flow rate is about 0.4 gpm

(relatively high to make sure flow does not limit heat transfer and to keep

the reservoir well mixed).

The pumps are small (3 watt), submersible fountain pumps that are located in

the reservoirs.

This is a

small panel test in which the performance of

two small collectors is compared. One collector uses aluminum fins and

copper tubes with a layer of silicone caulk between the fin and the tube.

The 2nd collector uses the same construction with no silicone between the fin

and tube. Each collector heats a 29 lb charge of water in its own

insulated reservoir. The reservoir water is pumped through the collector

using a small submersible pump. The collector that raises the temperature

of it's reservoir the most is the better performer. The idea is that since

each collector is the same size, is heating the same amount of water, and is

exposed to the same sun, the only difference in reservoir temperatures will is

be due to the difference in the construction of the two collectors -- in this

case, the fin to tube gap being filled with air or filled with silicone.

The performance plot shows the

silicone filled gap collector starting about 1F below the air filled gap, and by

the end of test, the silicone filled gap collector reservoir is about 1F warmer

than the air gap reservoir.

Results:

| Collector Construction |

Start temp |

End temp |

temp Rise |

% of base |

| Test1: Silicone filled gap vs air filled gap |

|

|

|

|

| |

Copper tubes - Aluminum Fins -- Air in gap |

76.07 F |

127.60 F |

+51.53 F |

base |

| |

Copper tubes - Aluminum Fins -- Silicone in gap |

75.20 F |

128.00 F |

+52.80 F |

+2.5% |

| |

So, the panel with the silicone caulk

filling the tiny gap between the copper tube and the aluminum fin showed about

2.5% better performance. I did two similar tests with the collector that

uses PEX tubing and aluminum fins. The results were similar with about 4%

better performance for the silicone filled gap collector.

Rough Calculation Comparing Silicone

in Gap to Air in Gap

This is an analytical estimate of the

performance improvement you might expect to see for the silicone filler in the

gap between the tube and fin:

Thermal Conductivity of air = Kair =

0.025 w/m-C

Thermal Conductivity of silicone

caulk = Ksil = 0.25 w/m-C

Consider a 1 meter long segment of

aluminum fin and tube:

Solar collection area for this 1

m of fin and tube = (0.152m wide)(1 meter long) = 0.152 sqm

Solar Radiation on 1 m of fin and

tube = (1000 watt/sqm)(0.152 m^2) = 152 watts

Assuming a typical 50% collector

efficiency, the solar radiation going into 1 meter of tubing = (152

watts)(0.5 efic) = 76 watt

So, the 1m of fin must transfer

76 watts to the tube through the air or silicone filled gap. What is

the temperature difference across the gap that is required to transfer this

76 watts?

Heat transfer area - fin to tube

= (1.580 cm)(Pi)(100cm) = 496 sqcm = 0.0496 sqm = Aht

This is the heat transfer area

from the fin to the tube that the 76 watts must be transferred through.

Assume that the average thickness

of the gap is 0.004 inches = 0.0102 cm = 0.000102 m = Tgap

(equal to a thin sheet of paper).

Heat Transfer across the gap = Qgap =

(Aht)(dTgap)(K/Tgap)

Where dTgap is the temperature

difference across the gap -- rearranging for dTgap:

dTgap = (Qgap) (Tgap) / ((Aht) (K))

So, for the silicone filled gap, the

temperature difference required across the gap to transfer 76 watts is:

dTgap = (76 watt) (0.000102 m) /

((0.0496 sqm)(0.25 w/m - C)) = 0.63 C = 1.1 F

If you use

this collector

efficiency calculator, and assume typical collection conditions (60F

ambient, 120F storage temps), then the collector efficiency drops from 52.3%

down to 52% -- a drop in efficiency of 0.3% -- this is the result of

increasing the absorber (fin) temperature by 0.63 C (1.1F) to overcome the

thermal resistance of the 0.004 inch thick silicone caulk layer. This is

equivalent to a 0.6% drop in heat output from the collector compared to a a

collector with a perfect fin to tube connection.

With air in the gap instead of

silicone caulk, the temperature difference across the gap would have to be:

dTgap = (76 watt) (0.000102 m)

/ ((0.0496 sqm)(0.025 w/m - C)) = 6.25 C = 11.2 F

Using the collector efficiency

calculator, the efficiency would drop from 52.3% down to 48.6% -- a drop of

3.7%. This is a bit more than the 2.5% result from the test above, but

generally in agreement.

So, both the test panel and the

calculation suggest a gain in collector output in the area of 2 to 6% for

filling the gap between the fin the tube with silicone caulk. In addition,

the caulk bonds the fin and tube together tightly so that there is no tendency

for them to separate as thermal expansion and contraction work the collector

over time.

If one were able to buy and use a

thermally conductive silicone caulk like this

CHO-THERM 1641, the temperature drop across the gap would be reduced by a

factor 3 to about 0.2 C (0.4F), and the efficiency drop to overcome the thermal

resistance of the gap would be reduced to only 0.1%. This would be a gain

in efficiency over the plain silicone of 0.2%, and a heat output gain of about

0.5% -- this is in the nice to get category, but probably not worth paying a

great deal more.

I've asked for a sample of the CHO-THERM

1641, and if they come through, I'll do a small panel test with it.

The calculation assumes that the

presence of the silicone in the gap does not make the gap any thicker. It

has been suggested that the gap might be thicker with the silicone because of

its resistant to being squeezed out. After some playing around with some

short sections of tube and fin to see how well the silicone squeezes out, I

don't think that this is a problem as long as firm pressure is applied when

stapling. Any excess silicone only has to work its way down to the bottom

of the tube where it is easy for it to be squeezed out between the bottom sheet

and the fin. I also sectioned one of the early test panels with a saw at 4

inch intervals, and did not see any evidence of the silicone resulting in a

larger gap. You do need to use moderation in applying the silicone to the

fin groove, and to use lots of pressure when stapling so that any excess

silicone is squeezed out. It is a good idea to just make a test section a

couple feet long, then let it cure for a day, and then cut across it in a couple

locations to see if you were successful in keeping the gap small. Spraying

a mist of water into the air around and in the fin gap before applying the

silicone will allow the silicone to cure more quickly.

Gary April 7, 2009