Search

The Renewable Energy site for Do-It-Yourselfers

Small Panel Tests

of copper and PEX collectors

The tests described below compare the performance of the traditional

solar water heating collector that uses copper tubing soldered or welded

to copper heat absorbing fins to these two less expensive DIY collector

options:

The PEX tubing/aluminum fin collector...

The copper

tubing/aluminum fin collector...

These two

collectors can be built as a DIY project for $4 to $6 per sqft compared

to the $25 per sqft (plus truck freight) for all copper commercial

collectors.

These tests look at

how well these DIY collectors perform compared to the all copper

traditional construction.

|

|

Page Directory

The Test Plan

and Setup

I built a small test collector for

each of the three collector types, and ran them

side by side with each connected to identical small insulated reservoirs

containing the same amount of water. During the test, water is pumped from

the reservoir through the collector and back to the reservoir -- the water

in the reservoir heats up as the test progresses. The collector with the better

performance heats the water in its reservoir to a higher temperature, and the difference in final

temperatures in the two reservoirs is an indicator of how much better one collector performed than the

other.

I learned this technique form

Alan Rushforth, and I like it -- its easy and cheap to setup, and since each

collector is subjected to the same sun exposure, same reservoir size,

same amount of water, same ambient temperature, same wind, same pump, same heat losses... a lot of the variables that drive you crazy in

trying to compare collector performance are eliminated.

The picture above shows the test

setup. The collector construction being tested is on the left,

and the baseline collector using copper pipe soldered to copper fins is on

the right. The absorber and glazed area are the same for the two

collectors, and they both face the same direction. The two ice chests are each

loaded with 41 lbs of water. Identical, small submersible pumps are located

in each ice chest and pump water into the lower hose on each collector.

The water returns to the ice chest through the upper hose. Every attempt

is made to make the conditions for the two collectors identical so that only the

efficiency of each collector impacts the final temperature difference in the

reservoir temperatures.

Sun intensity is measured with an

Apogee pyranometer that is visible on the upper part of the stand -- it faces

the same direction as the collectors.

The reservoir temperatures are

monitored and logged with thermistor temperature sensors using an Onset Computer

logger.

Ambient temperature is logged at a

nearby, shaded location. The reservoir temperature sensors are located

near the pump intake on each reservoir, but the temperature is nearly constant

throughout the reservoir.

The flow rate through the collector

is fairly brisk (about 0.4 gpm) -- this keeps each collector operating at its

best efficiency, keeps the collector pipes filled, and keeps the reservoir

well mixed and at a uniform temperature.

Each pumps draws 3 watts (as measured

on a Kill-A-Watt meter), and this would tend to heat the water in the reservoirs

a bit -- about 0.25 F per hour. While the reservoirs are

insulated, they still lose some heat, and this would cause reservoir temperature

to drop a little -- about 0.4F per hour at mid test. But, the pump heating

and reservoir cooling effect each panel by the same amount, and have a small net

effect compared to the solar heating of the water.

Construction of the Test Collectors

Baseline Collector with Copper

Tubing Soldered to Copper Fin:

|

This panel has the same construction

as many traditional commercial solar collectors. It uses half inch copper

pipe to convey the heat transfer fluid. The copper pipe is soldered

continuously to copper fins to provide a very good thermal connection from the fins

to the pipe.

The copper fin is 0.018 thick --

somewhat thicker and more conductive than is commonly used in commercial

collectors. The fins are painted flat black.

The collector is glazed with 93%

transmittance SunTuf corrugated polycarbonate glazing -- very close to the

tempered high transmittance glass used on most commercial collectors. The

polycarbonate used also has similar IR transmittance characteristics to glass,

so the losses out the glazing should be about the same.

The back of the panel is insulated

with 2 inch polyisocyanurate insulation to R13.4 -- somewhat more than is used

on most commercial collectors.

The absorber on this collector is

painted flat black. This is typical of a number of

commercial collectors, but some commercial collectors use a selective coating

instead of black paint, and these result in about a 6%

improvement in efficiency under typical conditions. There are some

DIY selective coatings that could be used to gain back some of this if desired,

although they are generally not as good as the commercially applied selective

coatings.

Anyway, the idea was to make the

performance of this collector be as close to a typical all copper commercial

collector as I could, so that it could act as a baseline to measure the

performance of the other collectors. This collector is referred to as the

"baseline" below.

|

All Copper Test Collector

All copper test collector. All collectors

are identical in size, glazing, insulation,

reservoir size, pump, ... |

|

Close up of copper tube, copper fin, and solder joint. |

PEX Tubing with Grooved Aluminum Fin

Collector:

|

This collector uses half inch

PEX-AL-PEX to convey the heat transfer fluid.

The fins are made from 0.018 aluminum sheet. Each fin has a groove formed in it that fits

the PEX tube snugly.

There is a 2nd narrow sheet of

aluminum under the PEX tube (see picture) that overlaps the grooved piece on each side of the

tube, so the tube is essentially wrapped for its full circumference with

aluminum fin.

The absorber is painted with

the same flat black paint as is used on the copper baseline collector.

A silicone caulk is used to fill any

tiny gaps remaining between the PEX tube and the aluminum fin. The idea of

using the silicone caulk is that it is about 10 times more conductive than the

air that would otherwise fill the gap.

The construction details for this collector are shown here ...

|

The PEX/aluminum test collector. |

|

PEX tubing and aluminum

heat collection fins. |

Copper Tubing with Grooved Aluminum

Fin Collector:

|

This collector is constructed in

exactly the same way as the PEX collector described above except that instead of

PEX pipe, copper pipe is used.

So, this construction gives you the

high conductance tube wall of copper along with the easy assembly and the less

expensive aluminum fins, and no soldering of the pipe to the fin.

The construction

details for this collector are shown here ...

|

|

Test Results

Three tests have been done to date --

the results are discussed below and shown in the table below .

Test 1: Copper Baseline vs PEX

Collector with Grooved Aluminum Fin:

The PEX tube with grooved aluminum

fin collector does 84.2% as well as the baseline all copper collector.

Considering the low thermal conductivity of the PEX tubing wall, this is (I

think) very good.

Test 2: Copper Baseline vs Copper Tube with Grooved Aluminum Fin:

The copper tube with grooved aluminum

fin with silicone between does an amazing 96% as well as the baseline all copper

collector.

See also the temperature plot below

for Test 2 below.

Test 3: Copper Baseline vs Copper Tube with Grooved Aluminum Fin:

This is the same as Test 2 except

that half the water (20 lbs) is used in the reservoir so that higher

temperatures will be reached.

The idea is to make sure that the

relatively low temperatures reached in tests 1 &2 were not effecting the

performance differential between the baseline and test collectors. It

shows the same 96% of the baseline collector performance.

See also the temperature plot below

for Test 3 below.

This table shows starting and ending

temperatures for the two reservoirs over the full length of the test.

| Collector Construction |

Start temp |

End temp |

temp Rise |

% of base |

| Test1: Copper Tube - Copper Fin VS PEX tube

- Aluminum Fin |

|

|

|

|

| |

Copper tubes - copper fins (soldered) |

56.5 F |

107.8 F |

+51.3 F |

base |

| |

PEX tubes -- Aluminum Fins (groove and seal) |

56.1 F |

99.3 F |

+43.2 F |

84.2 % |

| |

| Test 2: Copper Tube - Copper Fin VS Copper Tube -

Aluminum fin |

|

|

|

|

| |

Copper tubes - copper fins (soldered) |

55.9 F |

115.1 F |

+59.2 F |

base |

| |

Copper tubes - aluminum fins (groove and seal) |

56.8 F |

113.6 F |

+56.8 F |

96.0 % |

| |

| Test 3: Copper Tube - Copper Fin VS Copper

Tube - Aluminum fin |

|

|

|

|

| |

Copper tubes - copper fins (soldered) |

52.8 F |

145.6 F |

+92.8 F |

base |

| |

Copper tubes - aluminum fins (groove and seal) |

53.2 F |

143.0 F |

+89.8 F |

96.7 % |

I think that a lot of reason for the

relatively small performance hit is the tight fitting groove in the aluminum

that wraps around most of the tube and provides a large contact area, as well as

the silicone to fill any remaining paper thin gaps.

I

Further improvement might result from

using a high thermal conductivity silicone between the tube and fin. These

are available, but I could not find a US source for small quantities.

Another reason that the performance

is closer than one might expect looking at the difference in tube wall

conductivity is that the all configurations are limited by the thermal

conductivity of the boundary layer of water just inside the tube wall -- it does

not matter how conductive you make the tube wall, you are still limited by this

boundary layer conductivity.

Tentative Conclusions

Commercial Copper Collectors

Commercial copper collectors offer

known high performance, long life, and good resistance to high

temperature stagnation temperatures for all tilt angles. But, they are

expensive (about $25 per sqft), and shipping is costly and can be very

frustrating (it took three tries to get an undamaged set of commercial absorber

plates for my Solar Shed collectors).

PEX Tubing -- Aluminum Fin Collector

From a cost effectiveness point of

view, the PEX collector does very well. If you are

willing to put the labor in, you can build the PEX collector for about 1/6 th the

cost of a good commercial collector, and only suffer a 15% loss in

performance. This makes the PEX collector 5 times as cost

effective as a commercial collector on a BTU per dollar basis. In most cases, the loss in performance can be made up

for just by making the collector a bit larger. You can literally build the PEX collector for about what it costs to ship a commercial collector to your

house!

The PEX collector must be protected

in some way from stagnation conditions. Collectors that are

stagnated in the summer at tilt angles close to the local latitude will develop

temperature that are (I think) to high for PEX -- temperatures over 250F.

In my case, I use a high tilt angle to control summer stagnation temperatures.

I think that the combination of a relatively large collection area coupled with

a high tilt angle (which gives improved winter performance) will give very good

year round performance and a larger winter time solar fraction. If

these methods of controlling stagnation temperatures are unacceptable, and you still want a

low cost collector, consider the

collector that uses copper pipe and aluminum fins (see below).

The commercial collector should have

a life of 30+ years and will probably need very little maintenance during that

time. The PEX collector may well also last 30+ years, but will likely need

some help along the way. By help, I mean that it will likely need some

painting and may need replacement of the polycarbonate glazing. The glazing on

my PEX collector is SunTuf polycarbonate, which is

guaranteed for "life", but my guess is that 15 years before new

glazing is needed

might be more reasonable. If carefully painted, the case should have

similar life and maintenance to a wood window or door frame. My

guess is that the PEX and aluminum fins will last a very long time, but this has

yet to be shown.

Because the baseline copper collector

is more efficient than the PEX collector, and there will be some weather conditions

under which the copper collector will be harvesting a little heat and the PEX

collector will be getting nothing. An example might be a cold day that has

a not so thick overcast. Without having looked at this in detail, I would

guess that this will amount to very little over a full season. When you

get to these kind of weather conditions, no collector is going to be collecting

much useful energy because there just is not that much solar radiation coming in

and the collector efficiency is low -- I believe that the bulk of the useful energy you collect over a season is

going to come from sunny or part sunny days.

Copper Tubing -- Aluminum Fin

Collector

For many people, I think that this

collector may be the best all around choice.

It provides nearly the same

performance as the baseline all copper collector, and about 14% better

performance than the PEX collector.

An advantage of this

copper tubing/aluminum fin collector compared to the PEX tube collector is that

it will not require special protection from stagnation temperatures. While

its not good to subject any collector (including commercial collectors) to long

periods of stagnation, the polycarbonate glazing, copper pipe, aluminum fins,

and silicone are all high temperature materials that should do well under

stagnation conditions.

At $6 per sqft it is $2 per sqft more

expensive than the PEX collector, but still a small fraction of the $25 per sqft

that commercial collectors commonly cost.

The build time is similar to the PEX

collector.

Small Panel Test Performance Plots

Test 1 Plot: Copper Baseline

Collector vs PEX tube with grooved aluminum fins

Long dash line is the baseline copper

tube/copper fin collector:

Half in copper pipe

Copper fin material -- 0.018 inch

thick -- fins are 6 inches wide

Copper fin is soldered to the

copper tube

Flat black paint

Solid line is the PEX collector:

Half inch PEX-AL-PEX tubing

Aluminum fin material -- 0.018 thick grooved to fit the PEX tubing -- fins

are 6 inches wide

Narrow aluminum strip under the

tube.

Silicone caulk to fill the paper thin gap between tube and aluminum

Flat black paint

Dash line is ambient temperature in a

shaded area about 10 ft away from collector

Green line is solar radiation on

collector plane in watts per sq meter

Reservoir is charged with 41 lbs of water.

Test 2: Copper Baseline Collector vs

Copper

tube with grooved aluminum fins

Solid line is the Copper Tube with

Aluminum Fin Collector:

Half inch copper pipe

Aluminum fin material -- 0.018 thick grooved to fit the the copper tubing -- fins

are 6 inches wide

Narrow aluminum strip under the

tube

Silicone caulk to fill the paper thin gap between tube and aluminum

Flat black paint

Long dash line is the baseline copper

tube/copper fin collector:

Half in copper pipe

Copper fin material -- 0.018 inch

thick -- fins are 6 inches wide

Copper fin is soldered to the

copper tube

Flat black paint

Sun and ambient temperature log did

not come out.

Ambient temperature was 63 to 65F.

This was a very clear sunny day --

sun intensity was probably similar to Test 1.

Reservoir is charged with 41 lbs of water.

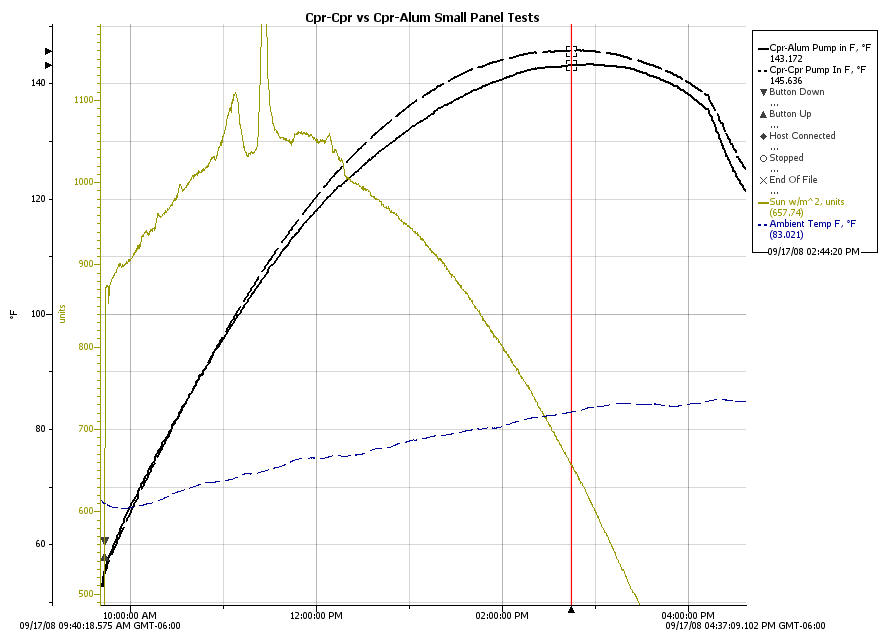

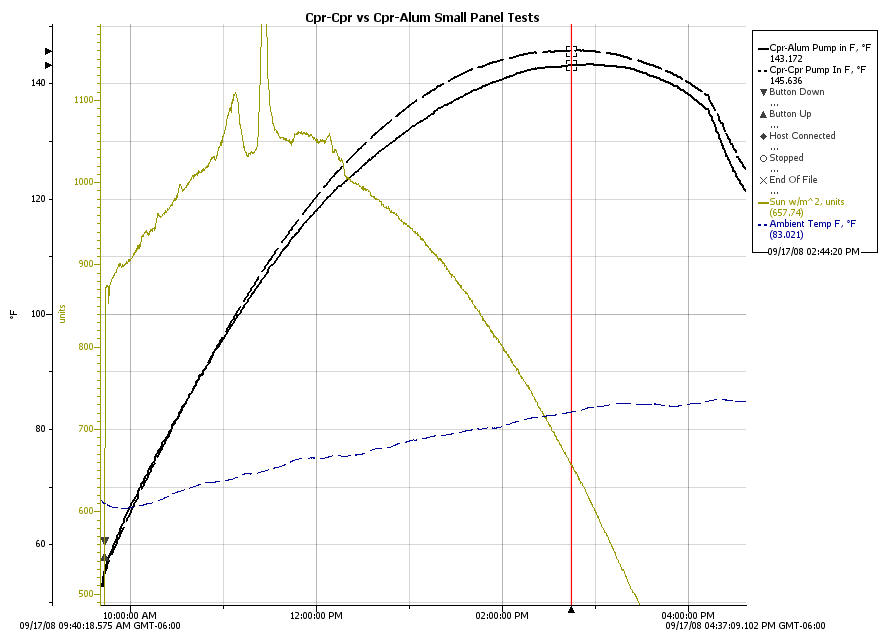

Test 3: Copper Baseline Collector vs

Copper

tube with grooved aluminum fins (20 lbs of water):

Test 3 is the same collectors as Test

2, but the water charge in the reservoirs was reduced from 41 lbs down to 20

lbs. This allows the collectors to get to higher temperatures to make sure

performance does not change with higher temperatures.

This is a ratio of 1.2 gallons of

water per sqft of glazing -- on the low end of what solar water heaters might

use.

Solid line is the Copper Tube with

Aluminum Fin Collector:

Half inch copper pipe

Aluminum fin material -- 0.018 thick grooved to fit the the copper tubing -- fins

are 6 inches wide

Narrow aluminum strip under the

tube

Silicone caulk to fill the paper thin gap between tube and aluminum

Flat black paint

Long dash line is the baseline copper

tube/copper fin collector:

Half in copper pipe

Copper fin material -- 0.018 inch

thick -- fins are 6 inches wide

Copper fin is soldered to the

copper tube

Flat black paint

Puky green line is solar radiation in

watts/sq meter

Dashed blue line is ambient

temperature F

Very clear sunny day.

Reservoir is charged with 20 lbs of water.

Follow-on

Small Panel Tests

Some additional small panel tests

that have been done since the ones above:

Silicone caulk in

tube to fin gap vs nothing in gap...

Higher thermal conductivity silicone caulk in tube to fin gap vs regular

silicone...

Gary September 12, 2008, September

28, 2008, May 26, 2011