Search

The Renewable Energy site for Do-It-Yourselfers

Homemade Pipe

Flare Tool for Solar Collectors

This page details how Kenneth made

the riser to manifold joints for his collector absorber plates.

I decided on ½ inch copper risers 6 inches apart with ¾

inch pipe headers. I saw

a tool on the internet to draw a half inch flange out of a ¾ pipe and

copied the tool using a Grade-8 fine thread bolt to make it. Grind the bolt

into a bell shape with a 5/16 shank then grind it flat on both sides to 5/16

thick ,then cut the slot.

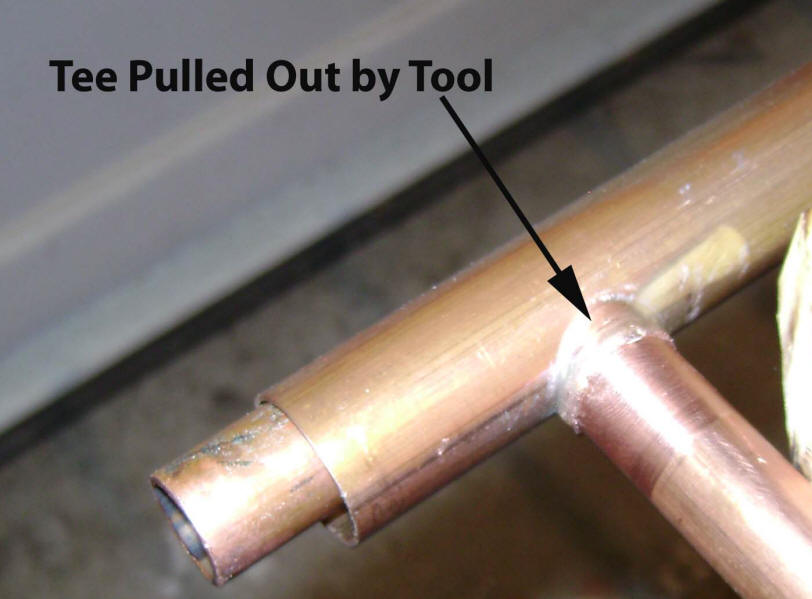

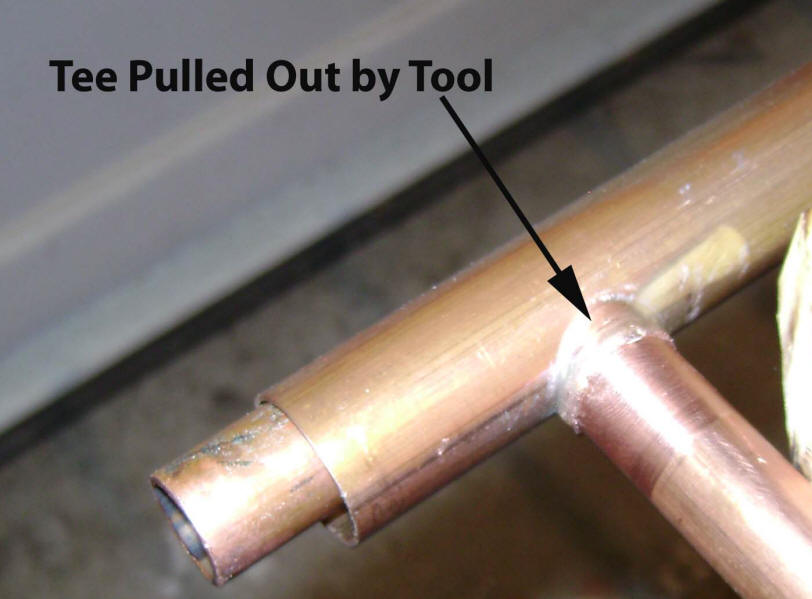

This shows the

result of Kenneth's homemade Tee Extracting tool. The tool "pulls out"

what is effectively a

short Tee fitting in the manifold pipe that the riser is inserted into a

soldered.

Click on pictures for full size

Here are some additional notes from

Ken on the T puller in response to an email question:

Hi, James,

The bolt is a fine thread 1/2 inch, but you could use a

13 mm.

The drive hex I put on the end is for a 11mm wrench.

The "block" can be made with a hard wood (if you use a

washer under the nut) by drilling a hole for the 3/4 pipe the lengthways, then

drilling a hole for the flare to fit into at a right angle to the first hole

about a 1/2 inch past the first hole. Then drill thru for the J hook

threaded end to fit thru finish by cutting off half the 3/4 pipe hole.

To use:

-

Drill a 5/16 hole in the pipe.

-

Then insert the J hook into the pipe.

-

Put the block over the J hook

-

Put a washer and nut (burr) on the J hook

-

Hold the nut and turn the J hook out of the pipe with

the flats or hex at the end of the J hook.

The J hook can be made with a hand grinder and a drill

press by grinding the head of a bolt into a bell shape

then grinding the sides off. Then use a cut off wheel to cut the slot. Use

a hard fine thread bolt so that the J hook doesn't bend when used.

Any more questions?

PS, It helps to heat the copper pipe when pulling the tee.

Kenneth W

Comments:

This Tee Puller is quite a neat gadget, and a

good way to make the manifold to riser connections. But, if you don't feel

up to making this tool, there are some other alternatives:

- You can buy a commercial

Tee Extractor, but they are kind of pricey -- about $230.

- For collectors up to about 6 ft

wide, you can just use half inch copper for both the manifolds and the

risers, and connect them using ordinary plumbing half inch Tees, which are

cheap. I've tried this and tested the

flow distribution, and its fine. Just make sure to tilt the

collector for good drain back, as the half inch manifold will make the

collector a little more sensitive to not draining properly and having freeze

problems. By putting two 6 foot collectors next to each other, you can

have a common center feed, and returns on the outside upper corners -- this

gives you 12 ft without a lot of hassle.

- You can buy reducing Tee's that

have the straight through pipe at 3/4 inch and the branch pipe as half inch.

Often the local prices for reducing Tee's are quite high, but

www.PEXSupply.com has a good price on

them. Be certain when you order that you get the half inch on the

perpendicular branch -- the PEX Supply catalog page makes it very easy to

order the wrong one. I used this method on my latest (just finished)

collector and it worked fine.

- You can braise the risers into

drilled holes in the manifold as Tom did

on his collector.

Braising is basically a high temperature form of soldering, and produces

stronger joints. I have tried just soldering half inch copper pipes

into a carefully drilled hole in 1 inch copper tubing using ordinary (420F

melting temp) solder, and it turned out surprisingly strong -- it may be OK.

It took a 30 lb load applied 6 inches from the riser to manifold joint to

fail the solder joint. If you have or know of a case where just solder has been used on a collector

and its been in service for some time, I'd like to hear about it --

gary...

So, lots of methods to choose from --

one of the benefits of having lots of people making collectors and trying new

designs :)

Back to the

main page...

Gary March 22, 2010