Search

The Renewable Energy site for Do-It-Yourselfers

Conductive Silicone to improve

performance of fin to tube thermal bond in solar collectors

|

These are the results of a test comparing the performance of two

solar collectors. Both use alum fins and copper tubes. Both

collectors use silicone in the grooved alum fins to improve the

conductivity between the alum fin and the copper tube. The

difference between the two is that one uses a thermally conductive

silicone and the other uses ordinary silicone.

The idea is to see if the thermally conductive silicone improves the

performance of the collector.

The test was run on 9/19/2010, but I'm just getting around to putting

the results up.

For

more on these small panel tests go here...

|

|

Construction

The construction of the collectors as whole and the idea behind the

small panel tests are covered here...

This page just shows the absorbers used for this test (with the two different

types of silicone).

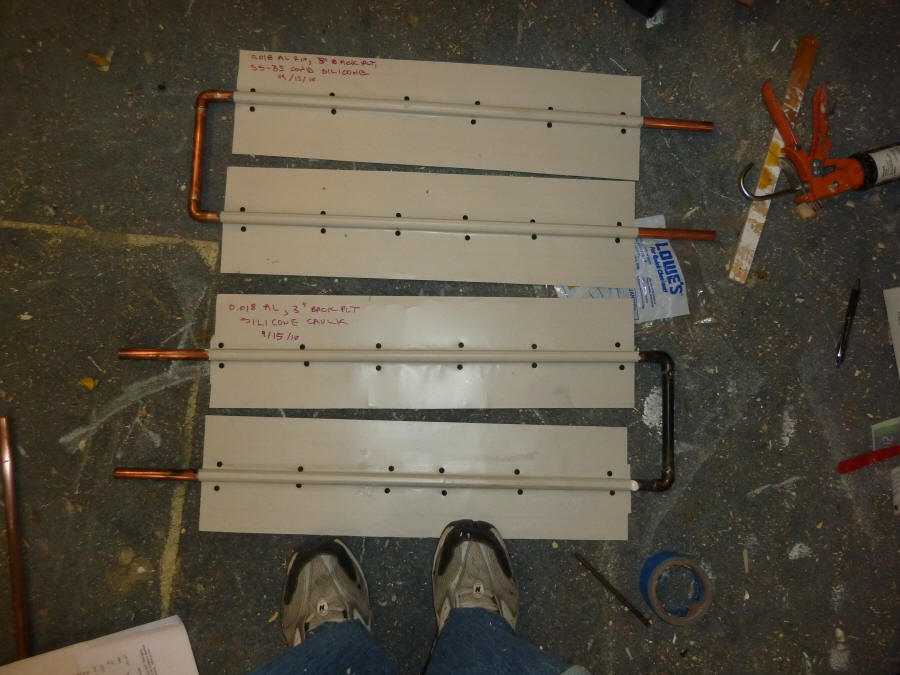

The picture just below shows the two absorber plates. They are meant to

be identical except that the top plate uses conductive silicone between the alum

fin and the copper tube, and the bottom one uses ordinary silicone.

The fins are 6 inches wide and made from 0.018 aluminum painted flat black.

The 2.75 inch wide alum backing plate is also 0.018 thick aluminum.

The regular silicone is Wall Mart store brand white.

The Conductive Silicone

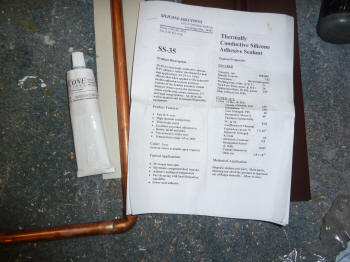

This is the data sheet on the Silicone Solutions SS-35 conductive silicone.

Other than being conductive, it has properties that are the same as a regular

silicone caulk (which is a good thing). It has about 3 times the

conductivity of regular silicone.

Click for full size.

Results

The green long dash line is the reservoir temperature for the collector with

the conductive silicone.

The purpleish short dash line on the bottom is the reservoir temperature for

the collector with regular silicone.

The top line is the sort of reference collector made with a copper fin

soldered continuously to a copper tube -- just for reference.

Ambient temperature averaged about 45F.

Sun intensity varied from about 800 w/sm at the start of the test down to about

650 w/sm toward the end.

Wind was near calm.

Here are the results from the plot above tabulated.

| Collector |

Start Temp F |

End Temp F |

Increase F |

Performance |

| regular silicone |

59.7 |

155.1 |

95.4 |

base |

| conductive silicone |

60.4 |

156.3 |

95.9 |

0.5 % |

So, the conductive silicone performed about half a percent better. This

is such a small difference that its hard to say that it might not just be

variables in the test process. I guess its safe to say that any advantage

of the conductive silicone is small.

If you see any problems with this test or the conclusions, I'd like to hear

from you.

This is a picture of the test in progress -- it shows the new better

insulated resevoirs and the stands that make it easier to keep the panels aimed

toward the sun. The water charges are weighed in

Gary November 28, 2011