Search

The Renewable Energy site for Do-It-Yourselfers

More on the Deep Mesh

Did a bit more on the deep mesh collector.

This is using the 2 by 3 ft collector that I've settled on for testing.

Tried progressively more layers of tighter materials for the absorber and measured the pressure drop and flow rate for the collector.

Pictures of setup

The collector box --- new wood blocks in the corners support the absorber frame and space it the correct amount of the back.

The wood spacer being glued to the inlet duct is to provide a surface to seal the absorber layers against so that inlet air cannot leak behind the absorber.

The dark brown rubber material all the way around the frame is epdm gasket that the glazing seals down to.

The two screen absorber from past test.

The layer of weed fabric being added to the 2 screen absorber. Its sits on top of a 3/8 this inch spacer which sits on the 2 screen spacer.

It is silicone sealed and stapled to the top of the 3/8ths spacer.

Absorber installed and sealed around the edges.

The wood spacer over the inlet duct opening compresses the absorber layers against the lower wood spacer with some silicone for sealing.

The static pressure tap being added to the inlet duct.

Made by taking a drip irrigator, cutting off one of the nipples and epoxying it to the duct.

Once the epoxy is cured, a 1/16th hole is drilled through the epoxy and the duct wall and the burrs are smoothed off on the inside.

Pressure drop is measured as the change in the static pressure between the tap just above and a similar one on the exit duct.

From the back of collector.

Fan at near end of inlet duct which enters collector at bottom. Inlet static pressure is measured where the black rubber tube goes to the duct.

Velocity is measured near the end of the duct from the collector exit. Outlet static pressure is measured where the black hose comes off the exit duct.

Collector setup from front with glazing on (this is the empty box test).

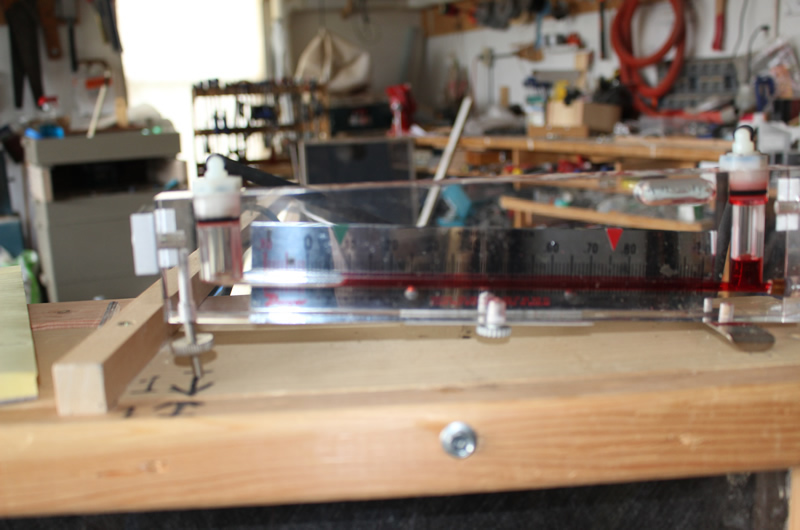

Dwyer oil manometer to measure pressure drop.

Close up of manometer.

I do have an electronic manometer, but I like this oil one as it does not drift or need calibration -- nothing can really go wrong with it.

The 2 layers of screen + 2 layers of weed fabric + 2 layers of felt absorber.

The Absorber Configurations Tested

Empty Box

Tested the empty box first.

Its just an empty box painted black inside -- no absorber other than the black back wall.

Wanted to see how much the pressure drop was with no absorber.

2 screens + 1 weed fabric

This setup has an absorber with 2 layers of window screen (from past test) plus one layer of a pretty dense (it seemed) layer of weed fabric.

Stackup is:

Back of collector

2 inches air

first layer of window screen

3/4 inch spacer (around edges)

2nd layer of screen

3/8 inch spacer

layer of weed fabric

1 inch of air

single Acrylic glazing

The absorber was pretty carefully sealed around the edges to prevent air from short circuiting around the edges.

The inlet duct was was pretty well sealed to the layers of absorber to prevent air from short circuiting up the back side of absorber.

2 screens + 2 weed fabric

As above, but with 2 layers of weed fabric instead of 1 layer.

The 2nd layer of weed fabric was right against the first layer of weed fabric.

2 Screens + 2 weed fabric + 2 layers of felt

As just above, but add 2 layers of black felt in front of the 2 layers of weed fabric.

The 2 layers of weed fabric and 2 layers of felt are right on top of each other (no spacers).

Results

Results for the 4 absorber configurations:

| Time |

Absorber Configuration |

Pressure drop (inches/h20) |

Velocity (fpm) |

Flow (cfm) |

Flow/sf (cfm/sf) |

| 11:45 am |

Empty box |

0.01 |

353 |

30.7 |

5.1 |

| 1:55 pm |

2 screen + 1 weed fabric |

0.022 |

288 |

25.1 |

4.2 |

| 2:30 pm |

2 screen + 2 weed fabric |

0.025 |

270 |

23.5 |

3.9 |

| 4:05 pm |

2 screen + 2 weed fabric + 2 felt |

0.025 |

233 |

20.3 |

3.4 |

| |

|

|

|

|

|

The Kumar paper recommends a minimum pressure drop of 0.1 inches of water and an approach velocity of 3.7 fpm to avoid the circulation from the back side of the absorber to the front.

Only got up to 0.025 inches of water, so it looks like no reasonable number of layers of weed fabric or felt is going to get to 0.1 inches of water (assuming the pressure measurements are correct).

Even saying that the tested absorbers got up to 0.025 inches is a stretch in that the empty box (no absorber) had a drop of 0.02 inches.

The velocity drops as the absorbers get thicker, so if I had adjusted the velocity so all were done at the same velocity, the pressure drops would have been higher -- but, the flow rates are all fairly high compared to what is needed for a high temp rise.

Maybe there is some alternative material that would provide more pressure drop? Please don't tell me to go drill 50,000 holes in sheet of something!

The approach velocity for 1 cfm/sf of absorber is 1 fpm, which is well below the recommended 3.7 fpm. It seems like its going to be hard to meet the 3.7 fpm and also get a very high temperature rise?

I can go ahead and test one of these configurations in the sun for performance, but it seems like it would be better to find an ab sober configuration that comes closer to the recommendations to prevent back circulation?

Gary

May 31, 2014