Search

The Renewable Energy site for Do-It-Yourselfers

A DIY Blower Door -- Easy to Build

-- Easy to Use -- Cheap

|

This page describes how to build and use a pretty good blower door

that you can build for about $30. You can use it to 1) find air

infiltration points in your house, 2) trace your progress in sealing the

house, 3) estimate your infiltration flow at 50 Pa (a blower door

standard), and 4) estimate your heat loss due to infiltration. It

basically does what a commercial blower door does, but less

automatically and less accurately. Also makes one helluva

ventilation fan.

Commercial blower doors are high capacity calibrated fans that are

installed in a door in order to measure how leaky your home is and to

allow easier spotting of leaks so they can be sealed.

Commercial blower door.

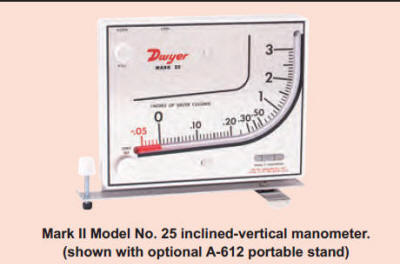

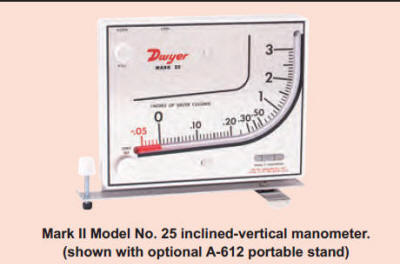

A standard blower door test uses the fan to depressurize the house to

50 Pascal (0.2 inches of water). The fans are normally variable

speed to allow them to be adjusted until the precision manometer

(pressure gage) indicates that the pressure difference between the house

and outside is exactly 50 Pa. The manometer computer then gives

the flow rate out of the house. |

|

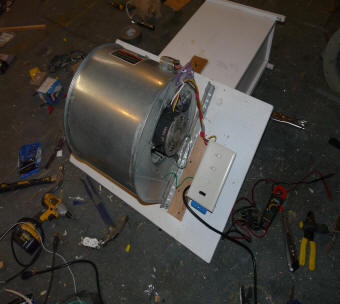

The DIY blower door uses a multi-speed furnace blower in place of the fan and

is fitted into a window rather than a door.

The furnace blower blower door mounted in a window.

The switches allow any of 4 speeds to be selected.

The meter to the right reads the difference between the pressure inside and

outside the house.

Page Index for the homemade blower door:

- Why build your own?

- Safety

- Building, wiring, and instrumenting

the blower door

- Using the blower door

- Estimating flow rates, ACH, and heat

loss

- References

- Comments/questions/suggestions

Why Would I Want to Build a Blower Door Rather Than Just Having Real A

Blower Door Test?

The advantages of having your own blower door are along these lines:

- Allows you to take your time finding the leaks -- you

can run it for hours if you like. You can work on sealing leaks over

months if you want to.

- You can measure how much things have improved after

each leak or set of leaks that you seal.

- With a little calculator work, you can 1) estimate your

total air infiltration, 2) estimate the heat loss this leakage causes, and 3)

see how it compares to other heat losses from walls, windows, ... That is,

you can get a full picture of your home heat loss, and know where to best spend

your money and time. At the end of your leak sealing you will know how

much you have actually reduced infiltration and how much heating fuel you will

save.

- If you are a home builder or contractor, having your

own blower door means you can check frequently as construction progresses to see

how tight things are and spot leaks while they are still easy to fix.

- If you ever want to ventilate your house at a high rate

for whatever reason -- this gadget will blow or suck a goodly amount of air.

One of the main reasons I decided to make a blower door is that I had a

blower door test done by my utility. It was fairly expensive ($200+), was

rather rushed with little time to look for leaks and really understand what was

going on, and in the end the report never came through despite a couple phone

calls. Building my own blower door allows me to take my time finding and

sealing leaks and to get a good idea what the leakage rate is for my house.

If you have a blower door test done by your utility (or other service), they

will likely point out some places where air is leaking, and you can have a go at

sealing them. But, unless you want to pay for a 2nd blower door test, you

won't really know how successful you were.

This DIY blower door does not, of course, have the flexibility, ease of use,

and accuracy of a good commercial blower door, but on the other hand its not

that difficult to build or use, its reasonably accurate, and it cost 1/100th of

what a commercial door costs. If you are in the business of doing

certified blower door tests, you need a good commercial blower door, but this

may be a good alternative for other folks.

If you build one, I'd love to hear how it works out.

Safety

There are safety issues that you need to pay careful attention to:

- The blower fan is powerful and can suck all manor of

things into it -- including fingers, hair, curtains ...

- You will need to do a little 120VAC wiring and this

poses an electrocution hazard.

- When using the blower door, you must be careful to turn

off or disable all combustion appliances (furnace, water heater, ...) because

the blower door depressurizes the house and can backdraft these appliances.

There are probably other hazards I've not thought of -- its completely up to

you to make sure that what you do is safe.

I take no responsibility whatever for any

property damage or injuries you may sustain while building or using this blower

door, or for any misleading or incorrect information in this article. Do

your homework!

Building the Blower Door

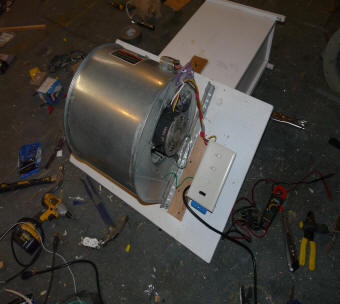

The pictures below show the blower door (actually a blower window) in

progress. Basically, its just a salvaged furnace blower mounted on a piece

of plywood that is cut to fit one of your windows. You could, of course,

cut it to fit a door if you want to, but window makes for a smaller and simpler

mounting of the blower.

The furnace blower is mounted to a piece of

5/8 inch thick plywood.

The opening is for the blower exhaust.

The plywood outer dimensions are cut to fit in

the window. |

The half hp used furnace blower just

before mounting on the plywood. |

Plywood and blower -- ready for mounting. |

Furnace blower mounted on plywood.

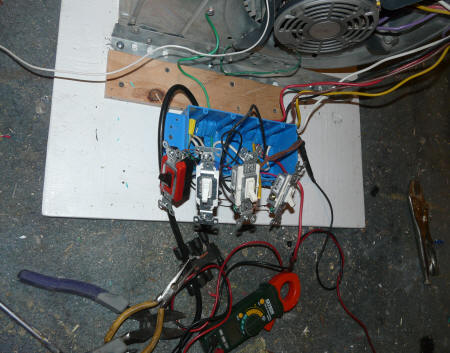

The switch box that sets the fan speed

is a regular 4 plex electrical box.

The switches are ordinary hardware store switches. |

Wiring the switches that select the

fan speed. See wiring diagram below. |

Ready to go in the window. |

Blower door mounted in a window.

The pressure gage is sitting on top of

the roll around cooler. |

Spacers are used to push the plywood to one

side of the window frame so that it seals

against the frame.

You can see the tubing going out through a hole

in the plywood -- the tube carries outside pressure

to the meter. |

Outside view of the blower door installed

in my shop window. |

Finding & Choosing A Furnace Blower

You can probably pick up a used furnace blower for free or cheap. I got

one some time back for another project for free from a local HVAC business -- I

just had to remove it from a furnace in their boneyard. The one I used on

this project came from the local Habitat Restore for $15.

The blowers commonly come in 1/3rd, 1/2, and 3/4 hp models -- typical

airflows are:

1/3 hp -- 1700 cfm on high, 1000 cfm on low -- about 8.5

ACH in a 1500 sf home on high

1/2 hp -- 2500 cfm on high, 1400 cfm on low --- about

12.5 ACH in a 1500 sf home on high.

3/4 hp -- 2600 cfm?

Just for reference, a commercial blower door is capable of about 5000 cfm

flow. So, there will be times when the furnace blower version will not be

able to reach the full 50 Pa depressurization where a commercial door would.

The model I have is a half hp that produces about 2500 cfm on top speed.

It will produce about 12 air changes per hour in a 1500 sf house, and if the

house is reasonably tight, it will pressurize it to 50 Pa (the standard for blower

door tests), or maybe even a bit more. If its unable to pressurize the

house to 50Pa, it will still produce plenty of flow to help in looking for

leaks, and after plugging enough leaks, the house will get tighter and

eventually get to the 50 Pa. A method is provided below to estimate what

the flow would be at 50 Pa for homes where the blower can't get it up to 50 Pa.

What kind of air change rate can this blower door achieve?

If you use a half hp furnace blower it will probably be able to move about

2500 cubic feet per minute of air out of the house on high speed. The pressure curve for

these furnace blowers is such that it will move about that amount of air on high

speed no matter how tight your house is.

If you have (say) a 1500 square foot house with 8 feet high ceilings, than

the inside volume of your house is 12,000 cubic feet. The blower will be able to do nearly

13 air

changes per hour. If your house is larger, then you will get a

proportionately lower number of air changes per hour. A very tight

house will test at around 0.5 air changes per hour, but many existing homes will

be initially be 10 air changes per hour or even more.

When you first try the blower door, if your house is large and/or leaky, the

furnace blower may not be able to depressurize the house to the full 50 Pa that

a standard blower door test uses, but it will still produce enough

depressurization to make it easy to find leaks. As you fix the leaks the

pressure will go up and you will probably be able to reach the standard 50 Pa.

Wiring for multiple speeds

Most of the blowers have three or four speeds, and its good to have access to

all of the speeds when testing.

The diagram below shows one simple way to wire the furnace blower motor so

that you have access to all 4 speeds by flipping switches.

The on-off switch (surprise) turns the power off and on.

The first three way switch selects fan speeds 1 and 2 in one position and

speeds 3 and 4 in the other position.

The upper right 3 way switch selects either speed 1 or speed 2 when the first

3 way switch is in the 1-2 position, and the lower right 3 way switch selects

speed 3 or speed 4 when the first 3 way switch is in the 3-4 position.

For example, if you want speed 2, you would put the first 3 way switch in the

1-2 position and the upper right 3 way switch in the "2" position.

Maybe there is a simpler or more elegant way to do this? But, this does

work fine and is easy to use.

You could just have 4 single pole switches with one switch for each speed, but

you would have to be VERY careful to make sure you turn one speed off before

turning the other one on. Or, a rotary 4 position switch would be good,

but I was unable to find one at a reasonable price.

The three way switches are just ordinary hardware store switches intended for

hooking up lights that can be switched on or off from two locations -- they are

single pole double throw switches, and I just use them to select one of two

hookups. I think that 20 amp switches are preferable since you switching

motor start currents.

The blower motor is the circle at the right.

.png)

For the blower I have, the motor wires are marked this way:

| Speed |

Wire Color |

| High (4) |

Black |

| Med-Hi (3) |

Brown |

| Med-Lo (2) |

Yellow |

| Low (1) |

Red |

| Common |

White |

The color coding of the blower wires does vary from blower to blower. For the ones I've seen, white

has been common and black has been high speed and red has been low speed, but

the colors for speeds 2 and 3 have varied. The motor label may tell you,

or you can hook them up and see what speed results.

The motor will also probably have two wires going to the run capacitor which

will probably be mounted on the blower housing. The capacitor must be

hooked up for the motor to run correctly.

The 4 switches being wired

|

Switches in use (it ended up upside down of course) |

Measuring Pressures

You can use the furnace blower door without having any way to measure the

pressure differential from the inside of the house to the outside, and it will

work fine for finding infiltration leaks. If you add the pressure

measurement capability, then the use of the blower door can be extended to check

how well your sealing is going, and to estimate your infiltration flow rate and

the heat loss due to this infiltration flow. The pressure being

measured is just the pressure difference between the inside of the house and the

outside -- for a given flow rate (blower speed), the lower this pressure is, the

leakier your house is.

Commercial blower doors use very sophisticated manometers that provide very

good accuracy and many automated features -- they also cost a lot.

Most of the time, I use a Dwyer Magnehelic meter that I picked up on ebay for

about $10 sometime back. A lot of them come up on ebay, or they are

available new from Dwyer for about $70. They are very well made. The one I have is 0 to 0.2

inches of water (0 to 50Pa). This gives nice accurate readings up to 50 Pa

-- I can easily read it to 1 Pa.

I think that an ideal range would be 0 to 100 Pa, and Dwyer does sell such a

meter new for about $70.

The ebay Magnehelic I use.

To measure the pressure difference between the house and outside, just place

the meter inside the house where you can read it easily. Then run a tube

from the meter to outside the house. I run this tube through a hole in the

blower mounting board. Be sure to have enough tube to get the outside end

away from the fan and to a sheltered area. When the blower is

setup to blow out (depressurize) of the house, hook the tube up to "high" port

on the meter, if the house is being pressurized, then hook the tube up to the

"low" port. Leave the other port open to the house air.

When the pressures are too high for the meter above, I use this lovely old

Dwyer oil manometer. I guess that being an old analog device myself, I

just like other old analog devices :)

Its quite accurate, nicely damped, hard to break, its obvious when its not

working right, never needs recalibration, and never needs software updates.

Another simple and cheap

manometer from Dwyer ...

Each small division is 0.01 inches of water, so it can probably be read to about

0.005 inches of water or about 1 Pa. Cost from Dwyer is $34 new.

I don't own any Dwyer stock -- I just happen to have accumulated some of

their stuff -- I'm sure other brands are fine also.

There are various digital manometers made by a variety of manufacturers --

these can be as low as $40. I don't have any experience with any of these,

but I suspect they would work fine. Just make sure that they will give

accurate readings at the relatively low pressures needed.

Measuring Airflow

On commercial blower doors another job of the manometer is to measure the

velocity pressure of the fan, and to convert that into a fan airflow rate so

that you know not only the pressure difference between the house and the outside

but also the airflow rate out the house that goes with it.

Furnace blowers have the nice property that over the range of pressure drops

of interest for blower door tests, the flow rate at fan each speed is

essentially constant. That is, regardless of the pressure difference

between the house and outside, the flow rate of the furnace blower on any given

speed will be nearly constant. So, if you can find the specifications for the

furnace blower and look up the flow rate for each speed at pressure drops in the

0 to 0.2 inches of water area, that will be the flow rate for your blower door.

Even if you can't find the flow rate specs, the flow rates for all of the half hp furnace blowers

I have looked at (all two of them) are quite similar. So, you might just assume your

blower is about the same.

Here are the flow rates for a Fasco half hp fan and the flow rates I measured

for my furnace blower:

| Speed |

Flow rate Fasco (cfm) |

Flow rate my blower (cfm) |

| 1 |

1220 |

1427 |

| 2 |

1450 |

1650 |

| 3 |

1800 |

1945 |

| 4 |

2400 |

2540 |

The specifications for the

Fasco blower listed above are listed on this Grainger catalog page...

I measured the flow rate for my fan with a very tedious 75 point velocity

survey across a duct connected to the fan blower exit. This is a fair bit

of work and takes an instrument that can measure flow velocities accurately --

probably more than most people want to do. So, using the average of the

two values in he table above is probably fine.

<add a page on the velocity survey

Using the Blower Door

Please don't do anything with your new blower door fan until you read through

the safety note above and read through this section and read the reference ...

This is not just the pro forma make the lawyers happy boilerplate -- there

really are safety hazards if you use the blower incorrectly.

Install the blower in the window:

< pic of it going in with spacers.

< include the installing the pressure gage

Be very careful not to let any curtains (or anything else) be drawn into the

fan.

Since the furnace blower is not variable speed and has only 4 fixed speeds,

its not likely that any of these speeds will give the standard 50 Pa of

depressurization. But, noting the pressure drop for at least two of the

speeds, its possible to interpolate a fairly accurate flow rate for 50 Pa.

Before you turn it on:

- Make sure nothing is going to get pulled into the blower when its

running -- curtains, nearby loose stuff, cats, pictures of the grandkids,

...

- Turn off all combustion appliances in the house -- gas water heater,

furnace, fireplaces, ... If these appliances are running when the

blower door is on, the blower is likely to back draft the exhaust vents and

pull combustion products into the house.

- Make sure any fireplace fires are dead out, and remove the ashes or

cover them with wet paper so that if the blower pulls a lot of air down the

flue it won't blow ashes all over.

- Close all the exterior doors and windows. Close fireplace dampers.

Close the doors or other openings to areas of the house that you you don't

heat. Pet doors can be big leaks, and you may want to leave them

initially open to see how big, but you will probably want to close them off

for most of the testing.

- If its a windy day, and you want to get accurate pressure drop readings,

you may want to wait for a more calm day.

- < check the lists>>>

Running The Blower:

Once you have double checked all the cautions above, you can turn the blower

on. I'd start with low speed, and once its running, go around the house

and make sure nothing is amiss.

Finding Leaks

I've not really seriously gotten started on using the blower door to find

leaks in my house yet, so this section is mostly reports from others. I'll

add my own experiences later.

Turn the blower door on low speed and note the inside to outside pressure

showing on the manometer. Increase the speed to get a good pressure

reading -- if you own a typical somewhat leaky house, you will probably end up

on high speed, but you may not want to use the highest speed if it pushes the

pressure over 60 or 70 Pa.

These pressures, by the way, are not going to pop your ears or anything like

that -- they are pretty modest.

Before you start looking for leaks, note the pressure differences you get on

all fan speeds so that you have a record of what the house started at.

Also note if you have closed off any parts of the house or sealed up pet doors

-- that is, note anything in the house configuration that would effect the

pressure differences.

With the blower running, start looking for leaks.

Most people report that using the back of the hand is about as good a way to

find leaks as any. You can wet the back of the hand with a wet cloth to

make it more sensitive.

There are also devices like smoke pencils or chemical smoke puffers that

generate a little smoke that will indicate airflow leaks. With the the

blower door depressurizing the house, an area that is leaking will stream the

smoke quickly away showing where the leak is. This video from

Minneapolis Blower Door shows some smoke testing for leaks.

Where To Look For Leaks

Inside the main living area, the usual places to check are:

- around windows,

- around doors

- along the floor/wall junction

- cabinets (like sink cabinets)

- electrical outlets

- around heater duct outlets

- fireplaces

- attic hatches

- whole house fan openings

- can lights

- pet doors (see below)

- any kind of dropped ceiling area

For the reasons listed just below under "High and Low", I would also check

things like outlets and baseboard for interior walls. These interior walls

may have openings through the top plate and into the attic (eg for wire or

plumbing), and the stack effect will tend to pull in air from the room, up

through the interior wall and up into the attic. The blower will result in

the reverse flow -- that is, into the room.

One thing we found some time back was that our dog door was a major leaker.

We replaced it with this dog door, which seals

much better... In starting our blower door tests, I simulated our old

pet door by pushing the flap open on our new door, and then just letting it

settle back to where the blower flow kept it part way open -- this change alone

dropped the manometer pressure bye 25%!

As you find and fix leaks, go back and check the pressure gage and see if you

can see any difference. Either way, you will probably want to keep a

record of what leaks you fixed and how much they effected the pressure gage

reading.

High and Low

For most homes (they say) the leaks listed above, while they may be

significant, are not likely to be the largest leaks in most homes. The biggest

leaks will more likely be from the living space up into the attic and from the

outside into the basement or crawl space (eg leaks along the rim joist just

under the flow). The reason for this is that the house is the stack effect

that the heated house creates -- warm air wants to rise up to the attic, and

this pulls cold air in down low. The stack effect will result in a

slight negative pressure in the lower part of the house which tends to pull

outside air in, and a slight positive pressure up high in the house which tends

to make air flow into the attic or outside.

If you have combustion appliances that are subject to backdrafting, you

should work on the attic (high) side of this equation first, and then move to

the basement or crawl space side.

Venturing into your attic can uncover a lot of evil leaks. Here are

some of them:

- The attic access hatch or pull down stairs can be a major leaker, so be

sure to test with with your hand or smoke. There are some commercial

and DIY approaches to sealing up

the hatch better...

- Once you get up in the attic, find the top plate of one of your interior

partitions and pull the insulation away so you can examine it along its

length. If you see wires or pipes coming up into the attic through the

walls top plate and the holes have not been sealed up, then your should

figure on sealing up these wire and pipe penetrations using something like

Great Stuff foam in a can.

- Look for any places where the insulation is stained dark by air from the

living space flowing up through it. When you see this kind of

staining, look for the air source causing the staining and seal it.

- Find the places where any kitchen or bathroom exhaust fans are installed

and make sure the housings are sealed to the ceiling.

- Can lights can also be a major leak path. If you have cans that

are approved for insulation contact, then pull the insulation away, seal

around the can, and pile the insulation back up on them. If your cans

are not approved for insulation contact, you can either replace them with

ones that are, or another approach is to buy one of the LED inserts for can

lights that converts the can to an LED fixture -- them tape up the holes in

the can with alum tape and seal the ceiling penetration with Great Stuff.

- Look around carefully for any dropped ceiling areas or discontinuities

in the framing that may have not been insulated or sealed properly.

Look at the places where there are discontinuities like dormers, porches

joining the house, etc. These can be very major leakers if not done

properly.

- Check chimney and flue penetrations. If they are not sealed, then

seal them with an appropriate high temperature material made for that

purpose.

- While you are up in the attic, check any heating or cooling ducts that

go through the attic. All of the joints and seams should be sealed

with duct mastic or tape that is approved for ducts (regular "duct" tape is

not approved and will have a very short life). Uninsulated ducts

should be insulated. Some of the studies show that on average homes

30% of the heated air never gets to the heat registers because it is lost

out of poorly sealed ducting -- 30%!

Clearly, this is all stuff you want to do before adding more insulation to

the attic as the new insulation will just make it more work to do the sealing.

One thing to note is that if the ceiling on the living space is not well

sealed from the attic, that a powerful attic exhaust fan can make these leaks

much worse by depressurizing the attic and will likely do more harm than good.

There are some good references on

measures to take in the attic here...

Basement and Crawl Space

Some of the things to look for in sealing the basement or crawl spaces:

- The rim or band joist around the periphery of the foundation is a

notorious source of air leaks. There are lots of places for

cracks: the sill plate to foundation, the sill plate to rim joist, the rim

joist to floor, and joints in the rim joist all make for cracks --

especially as the lumber drys out and shrinks. Some links below for

rim joist sealing.

- Plumbing, electrical and duct penetrations of the basement ceiling into

the first floor should be sealed with Great Stuff or the like.

- Any holes left open by the framers in the basement ceiling should be

sealed.

- Basement windows are usually not installed with much care and and may

have large infiltration leaks.

- As in the attic, heating or cooling ducts should be sealed with duct

mastic. If the basement is not a

conditioned space, then the ducts should be insulated.

- If you have a conventional ventilated crawl space, I would consider

converting it to a conditioned crawl space, which will reduce crawl space

heat loss and infiltration.

Some links for basement, crawl space, rim joist sealing:

http://howtohomeinsulation.com/index.html

http://www.finehomebuilding.com/PDF/Free/021189072.pdf

http://oikos.com/library/sealing_rim_joists/index.html

Again, I will add to this section as I progress through my leak exploration

process.

As far as expectations on how much you can bring the leakage down to on an

existing home, I think its hard to say. Just judging by the few reports

I've read, if you have a not so old home, you should be able to achieve at least

a 20% reduction in infiltration -- some people with older or just leakier

homes may be able to do MUCH better than that. Once you have done the

initial blower test and have an estimate of what the leakage is in Air Changes

per Hour at 50 Pa, you will have an idea where your house is on the scale of

fairly tight to very leaky, and that will give you a better idea what might be

accomplished.

Figuring Out Air Change Rate and Heat Loss

< need a full example that goes through 1)

measuring the pressures (careful location of static), 2) estimating flow at each

speed, 3) estimating flow a 50 Pa, 4) estimating heat loss for that flow, 5)

comparing to rest of house heat loss.

References

Thanks

I want to thank

Nick Pine and the folks at The

Hearth Forum for ideas and

advice.

Comments

.png)