Search

The Renewable Energy site for Do-It-Yourselfers

Title ..

Confirugation

Heating Performance

Thermal Camera Pictures

Temperature Environment

Stagnation

Configuration -- January 4, 2013 Test

In this test, the sunspace has been optimized for space heating the attached

house via the in the following ways:

- Large area of high tilt angle south facing glazing

- Double glazing in the form of twinwall polycarbonate

- Very low thermal mass in the sunspace (so heat goes to the house instead

of heating up sunspace mass)

- Non-glazed surfaces are well insulated and well sealed to reduce heat

loss to the outside

- The floor is insulated and low in mass

- All surfaces that see the sun are painted dark to absorb sunlight, and

are low mass so they heat quickly and transfer that heat to the air.

- Two fans to remove heated air from the sunspace peak -- these fans are

pretty well matched to the maximum rate at which the sunspace can produce heat with one

fan near the east end one near the west end.

This is a mean, lean, heat making machine!

In this test, black weed fabric is suspended vertically down from the

The idea is to see if having this vertical absorbing fabric will get the hot

air up to the ceiling more efficiently. The day two test drops this fabric

midway through the test, to compare h

One of the two 10 inch Grainger fans

that push air out of the sunspace.

The duct is extended outside to provide

a long straight duct for more accurate

flow measurements.

The vertical weed fabric screen used

in one of the configurations is also visible.

|

Setup for this test.

North wall is to left, weed fabric hung from

ridge line to right. The vertical pipe has

temperature sensors at 3 ft and 6 ft off floor

between fabric and north wall.

The blue tape spots mark places where surface

temps were taken. |

Same configuration with vertical weed fabric

and picture taken on south side of the fabric.

The vertical PVC pipe has two temperature sensors.

The blue tape spots mark places where surface

temps were taken. |

eat production with and without it.

Floor is some sand over dirt followed by

a layer of 1.5 inch thick Styrofoam

rigid insulation board. |

Looking without the vertical weed fabric

in place. The weed fabric hangs

from the plastic pipe running below the ridge.

The floor is dirt covered with 1.5 inch

Styrofoam insulation with some plywood

walking strips laid on it, and black weed

fabric on top.

The two PVC pipe posts support temperature

sensors. |

Sunspace on one of the test days.

The two "tunnels" extending east and west from

the lower south corner preheat the flow

of inlet air a bit. |

Inlets and Outlets

The inlets for the sunspace are located on the east and west walls down low

and just behind the south glazing. In an attempt to prewarm the air coming

into the inlet vents, a solar preheat tunnel was added to each inlet (see

picture) . while the inlets were cut as 1 ft square holes in the

wall, they have been reduced to about 3 inches tall by 12 inches wide to prevent

excessive flow and velocity through the inlets -- especially during windy times.

The outlets are located in the east and west ends near the peak. Each

outlet has its own Grainger 10 inch fan and is located about 4.5 ft from the

east (or west) wall. A straight flex duct runs from the fan outlet to the

wall and outside the wall, the duct is extended another 6 ft by a straight 10

inch diameter metal duct. The long straight duct run from the fan is

intended to give steady and straight flow at the outlet where velocity is

measured.

Performance

This was a gang busters clear day -- not a hint of a cloud all day. Its also only a couple weeks after the Winter Solstice, so the days are short

and the sun is low in the sky (about 23 degrees at noon). The outside air

temperature was in the 20'sF. Wind was generally light.

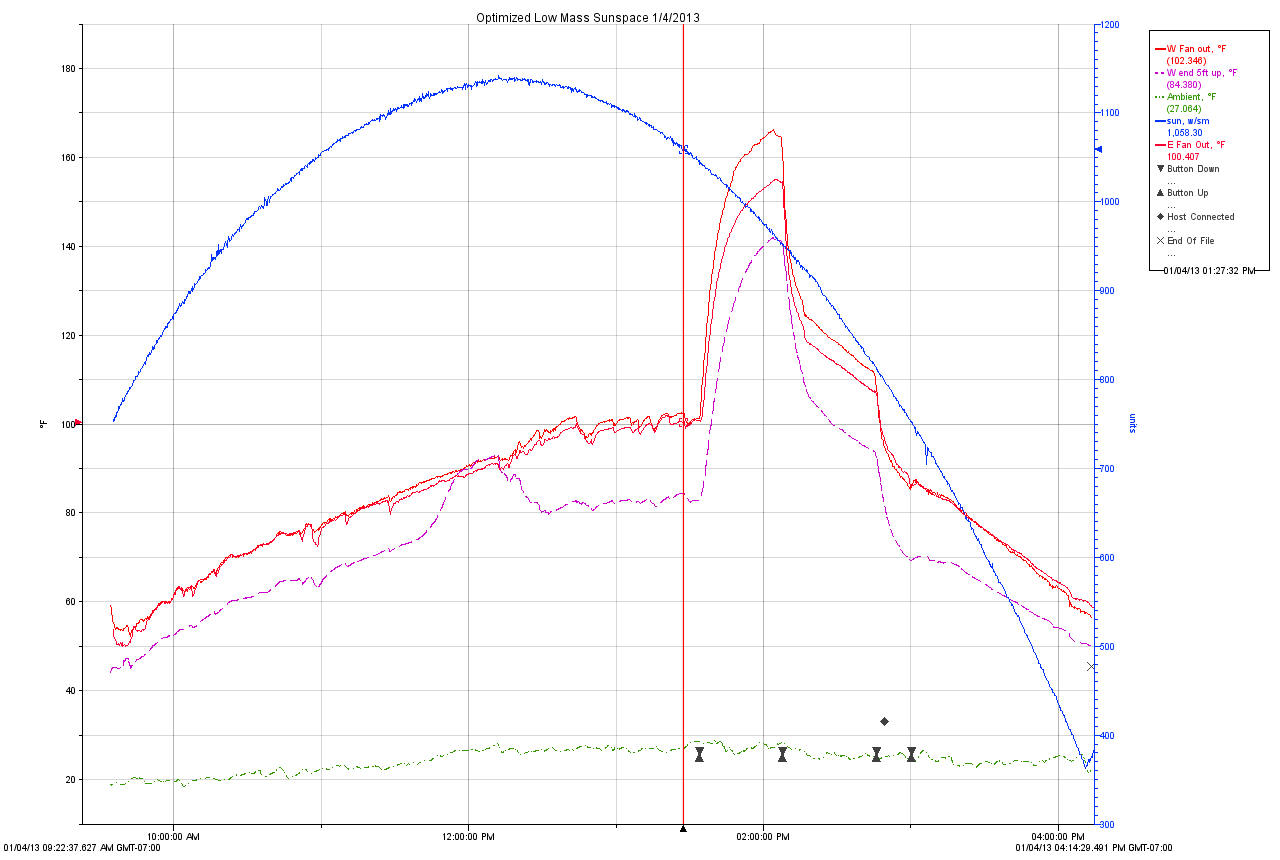

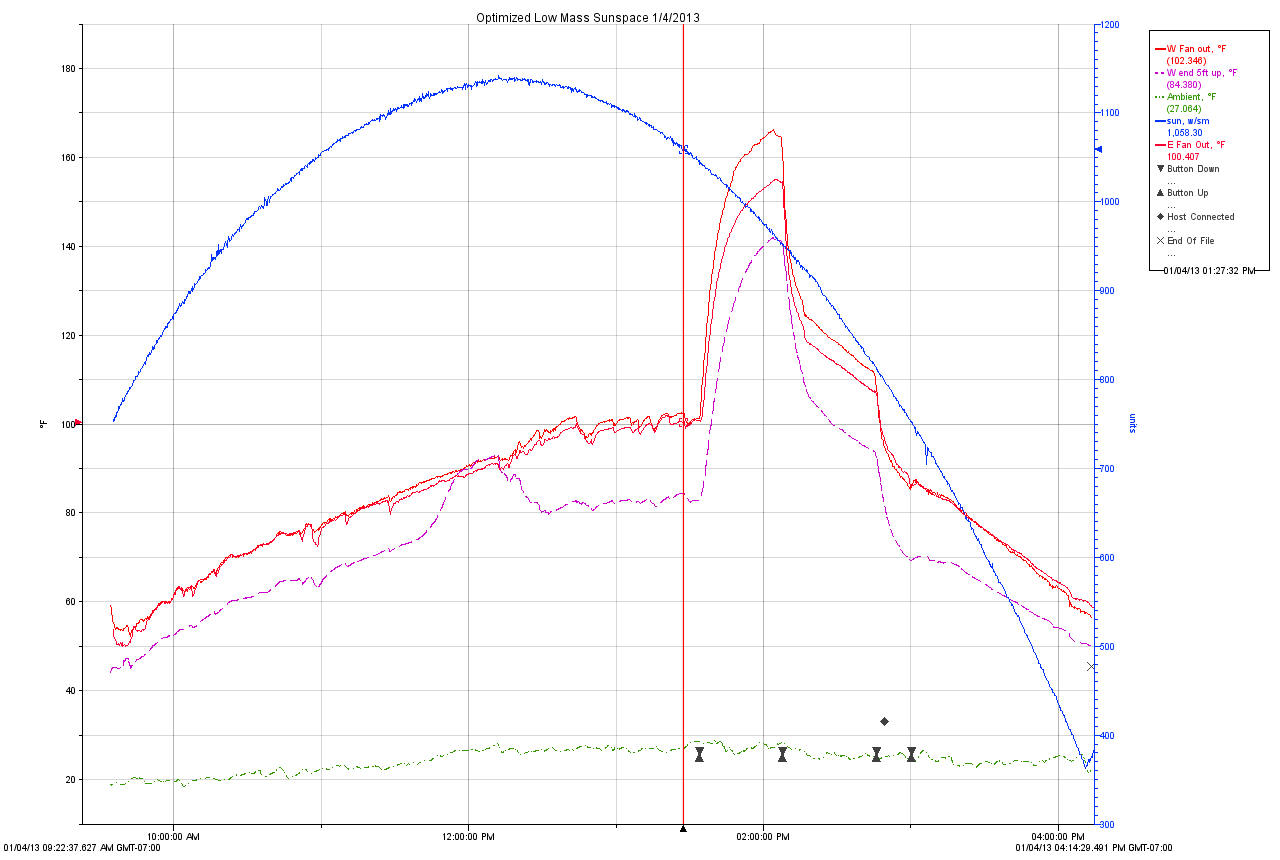

Blue solid line -- sun intensity (w/sm)

Red Lines -- Fan outlet temperatures for East and West fans (F) -- this

is the temperature of the heated air going to the house for space heating.

Green dash-dot -- Ambient temperature (F)

Purple dash line - Temperature at about the 5 ft level in the sunspace (F)

The sunspace was run with the fans on to produced heat for the house from

about 9:30am to about 1:30 pm. At this point the fans were turned off to

let the sunspace stagnate. At about 2:15 pm the fans were turned back on

again.

Total flow rate for the outlet ducts was 670 cfm (based on 614 fpm at outlet

ducts).

Heat Production

Looking at the long period when the fan outlet temperature is around 100F and

ambient temperature is about 26F, the sunspace is producing 670 cfm with a 74 F

temperature rise.

Heat Output = (100F-26F)*(670 ft^3/min)*(0.061 lb/ft^3)*(60

min/hr)*(0.24 BTU/lb-F) = 43,550 BTU/hr (210 BTU/sqft of

glazing)

This is about what a typical 60K BTU gas furnace would

produce.

The heat output for the day looks like this:

|

Time |

Tout (F) |

Tin |

Trise |

Velocity (fpm) |

Duct Area (sf) |

Flow Rate (cfm) |

Air Density (lb/cf) |

Heat Out (BTU/hr) |

|

10:00 AM hour |

61 |

19.8 |

41.2 |

600 |

1.09 |

654 |

0.061 |

23668 |

|

11:00 AM |

76.4 |

22.3 |

54.1 |

600 |

1.09 |

654 |

0.061 |

31079 |

|

12:00 PM |

90 |

26.6 |

63.4 |

600 |

1.09 |

654 |

0.061 |

36422 |

|

1:00 PM |

99.5 |

27.4 |

72.1 |

600 |

1.09 |

654 |

0.061 |

41420 |

|

2:00 PM |

99.5 |

28.3 |

71.2 |

600 |

1.09 |

654 |

0.061 |

40903 |

|

3:00 PM |

87 |

24.8 |

62.2 |

600 |

1.09 |

654 |

0.061 |

35732 |

|

4:00 PM |

64 |

25.1 |

38.9 |

600 |

1.09 |

654 |

0.061 |

22347 |

| |

|

|

|

|

|

|

|

|

| Total |

|

|

|

|

|

|

|

231570 |

So, about 232K BTU heat output for the day -- about equivalent to 3.6 gallons

of propane burned in a 70% efficient furnace.

So, even this modest size sunspace can produce a lot of useful heat on a

sunny winter day -- even for the shortest days of the year.

Stagnation

The fans were turned off at about 1:30 pm just to see what the temperature

would to to with the sunspace stagnated. The inlet vents were blocked with

some (somewhat leaky) fiberglass insulation and the outlets were left open

-- so, there was likely some thermosyphon flow through the sunspace.

The temperature in the outlet duct gets up 166 F just before the fans were

turned back on at 2:15 pm -- it probably would have climbed a few more degrees.

A temperature sensor closer to the peak got up to ???.

So, not surprisingly, this thing gets pretty warm pretty fast with no

airflow. While these temperatures are not dangerously high, some

form of venting would be a good idea when the space heating fans are not

running.

The odd looking double slope to the cool down curve after the fans were

turned back on is because I initially forgot to pull out the fiberglass plugs I

put in the inlet vents. They came out around 2:45 pm, and the cool down

slope steepens reflecting more air circulation.

Efficiency

One difficulty with making efficiency estimates from the performance curve

above is that the even though this is a very low mass sunspace, it apparently

has enough thermal mass that its outlet temperatures and heat output lag a bit

behind changes in sun intensity. You can see this in the time period from

about 12:30 pm to about 1:30 pm -- in this time period, the output temperature

and heat output are nearly constant at just over 100F, but the sun intensity is

dropping from about 1130 w/sm down 1040 w/sm. I believe that if the

sunspace had even lower thermal mass, it would react more quickly to solar

changes.

This effect also shows up if you calculate efficiencies for the morning vs

afternoon. In the morning, the sunspace outlet temperature is lagging

behind the sun level increases and producing lower outlet temperatures than it

would if the sun just stayed steady at one level. In the afternoon the

sunspace outlet temperature drops more slowly than the drop in sun level because

the sunspace mass is losing heat and keeping the temperatures up. So, in

the morning the apparent efficiencies are around 45% while in the afternoon they

are more like 71% -- these are not really valid efficiency numbers in that

conditions are not steady, but they illustrate the lag effect.

To get the best idea of efficiency that I could, I looked

So, how does this compare with a good commercial collector under the same

conditions?

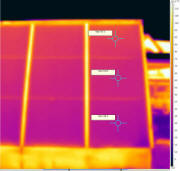

Thermal Pictures

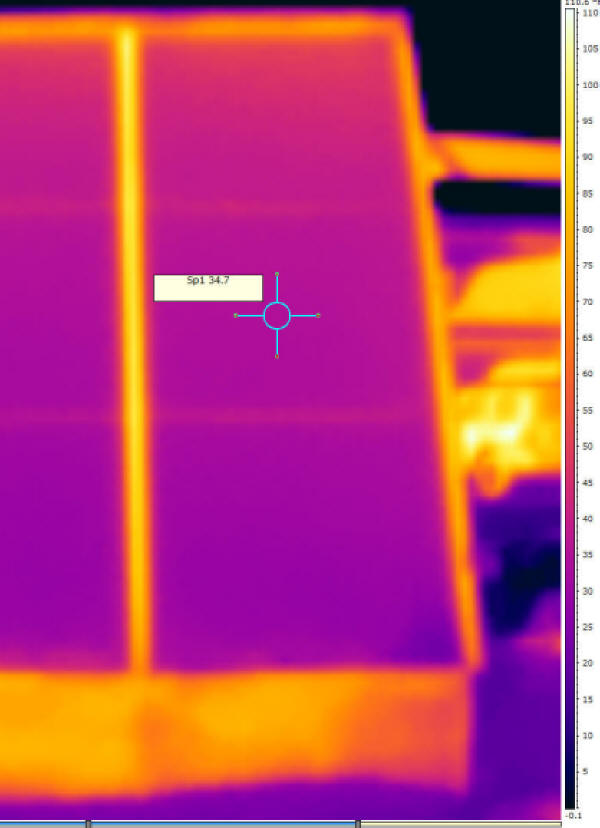

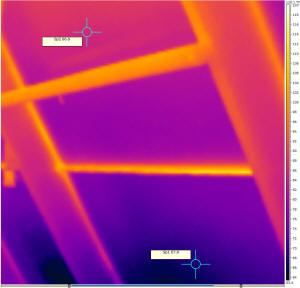

Glazing Temperatures

These pictures need to be clicked on to see the temperature labels.

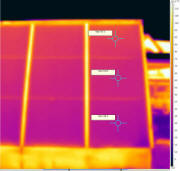

Outside of glazing.

Emissivity 0.95.

|

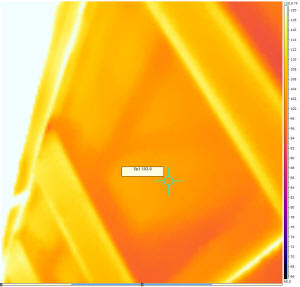

Inside of glazing -- top.

Top part of glazing panel. |

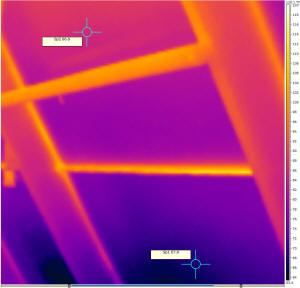

Inside of glazing - bottom.

Lower part of glazing panel. |

Glazing pictures at 1:46 pm.

The left picture above is of the outside of the glazing with temperatures

ranging from 38F at the bottom to 52F at the top.

The center picture is of the inside of the glazing near the top (the space is

confined enough that I can't get the whole panel in). The temperature is

103F on the inside surface, so the temperature difference across the twinwall

glazing is about 103F - 52F = 51F.

The right picture is of the inside of the glazing near the bottom with a

temperature of 68F. Temperature difference inside outside is 68F - 38F =

30F.

At this time, the conditions are:

Ambient temperature 28F

Fan outlet temperature 99F

Air temperature inside near glazing at bar 1/3 of way up

86F

Sun 1125 w/sm

Solar input 73K BTU/hr

Heat output = 41.5K BTU/hr

Losses = 73K - 41.5K = 31.5K BTU/hr

If you use a glazing average temperature difference of 40F, and R2 for the

glazing, then the rough heat loss through the glazing is (200 sf)(40F)/(R2) =

4000 BTU/hr, which is not remotely close to the 31K BTU/hr total losses -- I

would have expected closer agreement?

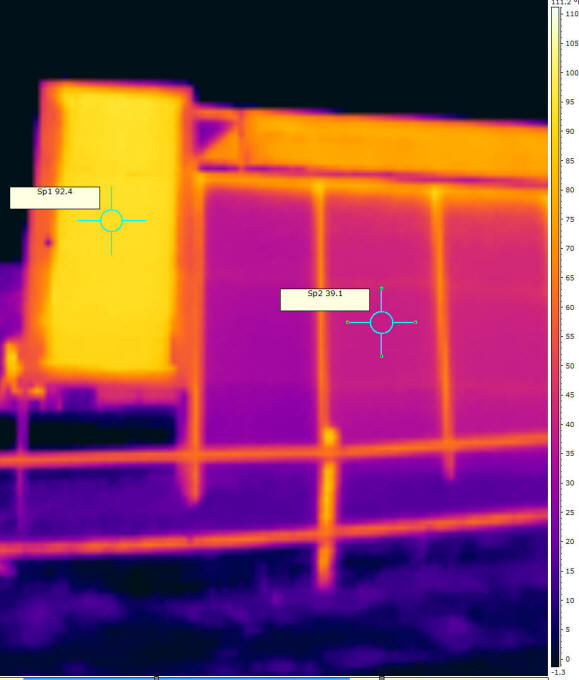

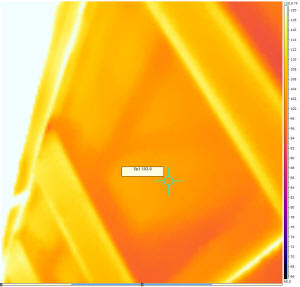

Just as an Interesting Item

I took some IR pictures of two other nearby collectors that face the same way

and are at the same tilt --

The left picture is the sunspace glazing at 3 pm with an outside temperature

of 35 F in the center.

The picture to the right has two collectors.

The right is the solar shed water heating collector with

twinwall glazing. Its outside temperature is similar to the sunspace

collector (4F warmer).

The collector to the right is an unglazed pool heating

collector being used as the prototype for the Off The Shelf DIY water heating

system. Its outside temperature is 92F.

All three collectors were operating at the time.

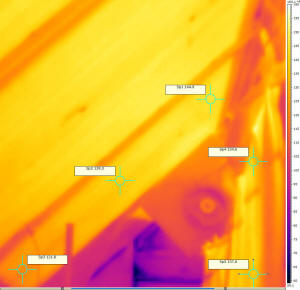

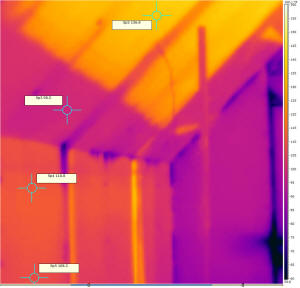

Inside the Sunspace

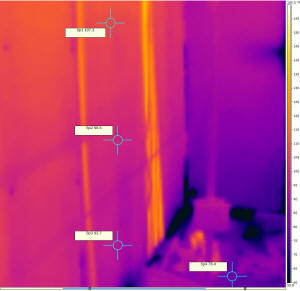

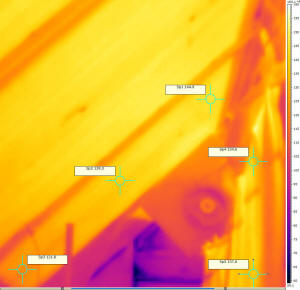

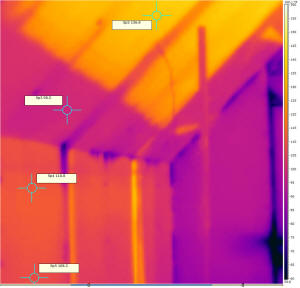

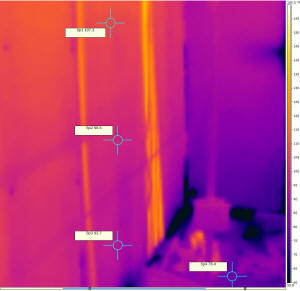

Back of sunspace (north of the vertical fabric curtain):

You have to click on these pictures to see the temperature labels

North roof behind fabric curtain.

Curtain is visible to right.

East fan is the circular item. |

North wall and north ceiling.

Lower part of north ceiling and all

of North wall are shaded by the fabric curtain. |

Lower part of North wall.

Fabric curtain out of view to the right. |

All done with temperature range of 60F to 160F and emissivity of 0.95.

Front of sunspace (south of the vertical fabric curtain):