Search

The Renewable Energy site for Do-It-Yourselfers

Lee's Gas to

Electric Lawn Mower Conversion

From Lee:

I know I'm only one guy, but I decided last year to seriously start

reducing the "carbon footprint" that my wife and I leave on this

fragile planet. Last year I added extra insulation in the attic and

wherever else I could, and replaced all my incandescent light bulbs

with CFLs. So far this year, I have replaced all my windows and

exterior doors with Energy Star versions built with insulated frames

and Low-E glass packages.

But these were all things that I bought, or had someone else install.

I wanted to build something from scratch, something that would prove

that anyone can do things to help. So I started searching about for

some do-it-yourself projects. Then I came across a couple of solar

charged battery-powered lawnmower projects and decided that I could do

something like this...

There are a number of battery-powered lawnmowers currently being

marketed commercially, but in my opinion all of them have very serious

shortcomings and problems, e.g., underpowered, flimsy, dangerous. In my

opinion, all of them were developed strictly to cater to the "pseudo

green" crowd, people who will buy anything that looks even remotely

eco-friendly regardless of the price or quality - the design parameters

being dictated strictly by the bottom line.

I started from a totally different place - I wanted a mower that looked

and cut and "felt" like a conventional gas engine mower. So I started

with a conventional mower deck and then worked backwards: to power a

21" mower, what HP electric motor would I need? And to power that

motor what size/type batteries would I need? And so on. For a first

attempt, I think I came close to what I had hoped for - a mower that

weighs and handles and cuts grass about the same as a regular gas

engine mower.

I had already discovered such sites as

(1) www.builditsolar.com,

(2) www.arttec.net/Solar_Mower/index.html, and

(3) www.appropedia.org/Solar_Charged_Lawnmower,

so I already had the benefit of other peoples' experiences. So before

I go any further, I want to acknowledge a giant debt of gratitude to

the people behind those web sites. I freely admit that anything I've

done could not have been done without them... If one of them looks at

my mower and sees something that looks familiar, it's because I stole

and plagiarized shamelessly. I plead guilty to recognizing a good idea

when I see it.

I started my project by phoning all the lawnmower repair places in my

part of town, asking if they had any 20-22" mower decks, minus the

engine, in reasonably good condition. One kind gentleman had exactly

what I was looking for, a 21" Troy-Bilt mower deck (engine was blown),

rear bagger version, complete with blade and dead-man handle/mechanism

(which I wanted to use for a start/stop switch) - he charged me only

$25 for what turned out to be an excellent deck.

That size mower is usually powered with a 4.5 to 5.0 HP gas engine, so

I started looking for a DC motor of approximately 1.5 HP, the rule of

thumb being that a 1 HP electric motor is equivalent to a 3 HP gas

engine. In

http://www.builditsolar.com/Projects/Vehicles/LawnmowerEngines.htm,

some unsung hero named "Paul" pointed me to a place from which I

purchased a 1.5 HP 24VDC motor for $69.95 - this turned out to be a new

Tecumseh motor actually designed for lawnmower use (I called Tecumseh

and tried to get some additional info on this motor or its application

in a lawnmower, but none of the people I spoke with knew anything about

it...)

I did some research on batteries and quickly decided that two 12V

batteries were much cheaper and more easily obtainable than one 24V

battery, and almost as quickly decided on the new AGM spill-proof

batteries. What I needed to know, but could not find, was the power

consumption of my new motor. The only thing I knew about it was the

sales pitch: 4.5 Amps no-load and 1.54 HP. A little math resulted in

the surprising figure of at least 44-48 amps at full load (1 HP = 746

Watts, or 1 HP = 746 x volts x amps) - and that's assuming 100%

efficiency. The confusing part was that the motor leads were #10 gauge

stranded copper, which is rated for only 30 amps. In the end, I

decided to split the difference, and assume 40 amps. I then purchased

two 22AH batteries, which by my calculations would give me approx 30

minutes of continuous mowing time before it was time to shut down and

recharge the batteries.

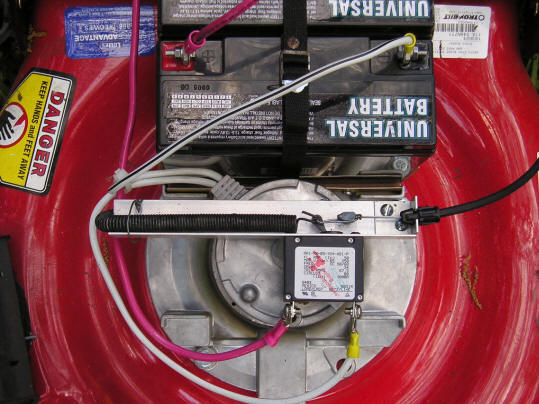

Since I was still a bit unsure about the power consumption of my new

motor, I also decided to hedge my bets with circuit breakers (actually

a combination switch and circuit breaker) and ended up purchasing three

different sizes: 30A, 40A, and 50A.

One lesson I learned is that components as described above cannot

usually be found at your local hardware store or even an electrical

supply house. There is apparently very little local demand for high

current DC parts such as switches, circuit breakers, AGM deep cycle

batteries, gauges, etc. Your best bet locally will be boating/marine

supply outlets, and the internet for everything else.

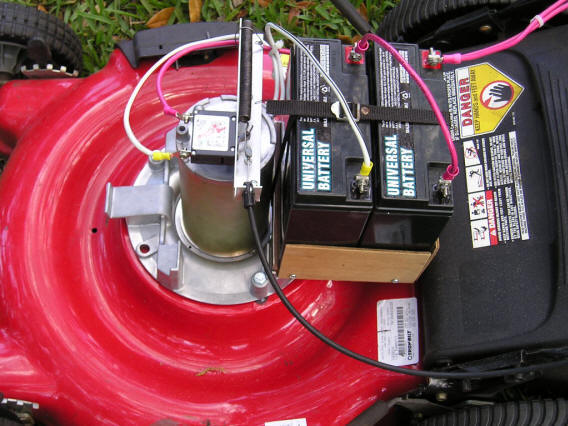

Anyway, the day finally arrived when I had all the components laid out

in front of me, and I could start assembling them. I mounted the motor

on the mower deck first. Before the deck became weighted down with

everything else, I installed the blade (easy, since the motor I had

purchased had a keyed shaft with standard mower threads) and adjusted

the cutting height so it was comparable to the height on the gas mower

it replaced - then I removed the blade and set it aside. I

experimented with various configurations and placements for the two

batteries - I ended up mounting them side by side just aft of the motor

- this seemed to give the best overall handling characteristics. I then

built a battery platform and securely mounted it to the deck and motor

housing - I added half-sides and a battery tie-down strap to keep the

batteries from jostling around while mowing.

I built a "dashboard" for the switches and gauges and mounted it about

3/4 of the way up the mower handlebars. On it, I mounted a 15 VDC

analog voltmeter with a DPDT switch so I could monitor the individual

battery voltages to determine when to quit mowing; and a 0-50 DC amps

analog ammeter and switch/circuit breaker so I could monitor the

current flow to the motor, to determine if I was working it too hard.

When I had everything mounted I started wiring it all together. I used

#8 gauge stranded copper wire since I was still operating on the

assumption that my mower normally would be pulling approximately 40

amps. I connected the motor, batteries, two switch/circuit breakers

(30 amp and 40 amp), and ammeter in series - the last connection was

made very gingerly.

On the first test, the 30 amp circuit breaker repeatedly tripped as soon

as both switches/breakers were turned on. After checking everything

out and determining that there were no short circuits or something

stupid like that, I replaced the 30 amp switch/breaker with a 50 amp

switch/breaker, resulting in a circuit with 40 amp and a 50 amp

breakers in series. Now the motor started running - after pulling

about 35 amps on startup, it settled down to about 5 amps - just as

advertised.

At this point, I physically removed one connecting wire entirely,

flipped the mower onto its side, and bolted the mower blade on again.

Turning it right side up, I re-connected the wiring, and tried it

again. It started right up - after pulling about 38 amps on startup,

it settled down to about 25 amps. I wheeled the mower out to the front

yard (which I had been purposely neglecting to mow for just such a

test...) and started mowing. It worked great! The sound it makes is

reminiscent of those big fans that churches used to have in the back of

the church during a hot Sunday service in the summer... Very relaxing

sound, and it brought back guilty memories of many sermons drowned out

- yet it's not so loud you have to wear ear protection, like I've been

doing with my gas mower.

-----------------

After using the mower 5 times, this is the current status:

(1) I replaced the 40 amp switch/breaker on the dashboard with a

regular 50 amp SPST toggle switch - the main on/off switch - it has an

orange ribbon on it to remind me to turn it off when done mowing. The

motor circuit now has two 50 amp switches in it - the 50 amp main

on/off safety switch, and a 50 amp switch/breaker that the deadman

handle is connected to.

(2) The motor will pull from 35 to 48 amps when starting up, depending

on whether it's hot or not. There may be other factors too, but I

haven't figured them out yet.

(3) When not actually cutting grass, the motor pulls 25-30 amps, and

when cutting grass it will pull anywhere from 30-50 amps, depending on

how high the grass is, or how fast I'm pushing the mower.

(4) The AGM batteries are designed to be fully charged at 13 volts,

and to be discharged down to 12 volts, so those are my operating

parameters (actually 24-26V since I have two 12V batteries in series).

The batteries can be used below 12 volts, but they will last longer if

not discharged below that point.

(5) I have found that I can mow my yard more or less continuously

(stopping only to empty the grass catcher) for at least 25 minutes on

one charge. The batteries were down to 12.2 volts at that point, so I

probably could go 30-35 minutes total. This is more than enough time

for me to mow my yard, so I am very pleased with the batteries I chose

for it - beginner's luck.

(6) I found that the analog voltmeter is worthless - it is neither

accurate enough nor rugged enough for this application. It is still

mounted on my dashboard simply because I like the look of it better

than the hole that would result if I removed it. I have a miniature

digital voltmeter that I carry in my back pocket that I use to check

the battery voltage from time to time, and find that works much better.

(7) The weight of the completed battery-powered mower, including

batteries and rear bag, is 92 pounds. The weight of this model of

Troy-Bilt mower with a 4.5HP gas engine and rear bag, is 85 pounds. So

mine is only 7# heavier - close enough.

(8) I am currently charging the batteries with a "smart" battery

charger I had on hand from another project. I want to build a solar

charger for my battery mower, but haven't done anything yet toward this

end except start researching possibilities.

(9) Parts/Price/Source List:

(a) $25 - used mower deck (including blade, blade mounting hardware,

grass catcher bag, and deadman handle/cable mechanism) - from local

lawnmower repair business

(b) $70 - 24VDC 1.5 HP motor -

http://www.surpluscenter.com/item.asp?UID=2007020121185584&item=10-2313&catname=electric

(c) $66 - two UB12220 12V 22AH AGM batteries @ $33 each -

http://www.batteriesasap.com/universal.html

(d) $16 - 50 amp AC/DC combination switch/circuit breaker -

http://www.go2marine.com/product.do?no=21343F&WT.mc_id=gb1

(e) $20 - DC ammeter, 0-50 DCA -

http://www.newark.com/jsp/level5/module.jsp;jsessionid=K0JOTQN4S14HCCXDUZ1G4IQ?moduleId=en_US/83247.xml

(f) $5 - SPST toggle switch rated 50 Amp DC - from local boating place

(g) $5 - 20 feet #8 gauge copper wire - from local Lowes store

(h) $5 - bunch of #8 gauge ring terminals - from local boating place

(i) $0 - misc aluminum, plywood, screws, nuts, bolts, etc

TOTAL $212 (shipping charges not included)

This has been a fun project - it kept me amused and doing something

that is at least marginally productive (mowing the lawn) - AND the best

part is knowing that I built something with my own hands that eliminated

one very noisy and smelly contributor to the sad state our planet is

in.

Lee at mvemjsunp2007 AT yahoo DOT com (change AT to @ and DOT to a period)

Lee will answer questions by email.

More pictures -- click to enlarge:

6/3/07 Update on the Tecumseh 90000A motor.

The motor Lee used is no longer available at the place listed above, but Lee

and Bill have found some alternative sources for the same motor -- here is the

info:

Hi Gary,

Received an email today from "Bill" who is going to build a battery-powered

lawnmower patterned after mine and I asked him what he was using as a source

for the Tecumseh 24VDC motor, since the Surplus Center where I purchased

mine is no longer stocking them. He told me he ordered one today from:

I did a little bit of Googling on the Tecumseh 90000A (also called TEC

90000A) and found another three possible (since I have not checked them out)

sources:

Gary 5/2/07, September 29, 2009