Search

The Renewable Energy site for Do-It-Yourselfers

Step-By-Step Construction Details

The pictures below go over the

construction of the tank in detail.

Its a simple project to build.

Click on pictures for full size

images.

Make the 2X4 Frame for the Box

|

Allow for insulation thickness between

the frame and tank. |

|

Check for square. |

Build the base frame sufficiently

large to allow for 2 inches of rigid foam board insulation around the sides and

back. In the front, allow about 3 inches of space behind the

glazing. The easiest way to get the size right is to place your tank

on the shop floor, and build the frame around it with the right clearances.

With the frame size established, glue

the corners and nail or screw.

Check the frame for square by

measuring the diagonals.

|

Fastening the verticals in place

on the bottom frame. |

Assembling the top frame on

the verticals. |

The finished box frame. |

Glue and nail the box verticals in

place. The height of the verticals should be measured carefully to allow

for the height of the tank plus two layers of 2 inches of rigid foam board insulation

under the tank. So, if the tank is 22 inches high, the verticals would be

22 + 2 + 2 = 26 inches high.

Now, assemble the top frame at the

top of the 4 verticals. The top frame is exactly the same size as the

bottom frame.

Cut and Install the Box Sides and

Back

|

Cut out the sides and back from

plywood. |

Note the filler 2X2 on back vertical,

and filler 2X4 on front vertical.

See note below. |

Attach the sides and back to the

box frame -- uses glue and

screws or nails. |

Next, cut out the plywood sides and

back for

the box.

On the front of the box, add the 2X4

filler to provide a surface for the side to screw to, and a place to attach the

collector glazing -- see the middle picture above.

On the back of the box, add a 2X4 filler along the back vertical to provide a

surface to nail the sides and back to -- the added 2X4 should be flush with the

outer edge of both the side and back of the top and bottom frame. The

picture shows this as a 2X2, but it should have been a 2X4, and should be

installed so that it is flush with both the back and side edges of the top and

bottom frame.

This added 2X4 provides a surface to

glue and nail the sides and back to.

See the middle picture above.

Box frame with sides and back installed. The collector glazing will

go in the front opening.

Install Top and Bottom

Cut out the top.

The top should be cut large enough to overhang 1 inch on each side, 1 inch on

the back and 2.5 inches on the front. The larger front overhang allows for

the thickness of the outer layer of glazing.

Cut a hole in the top that is

sufficiently larger for the stock to drink through. The drinking opening

for this tank is 16 inches deep by 22 inches wide.

The bottom can be cut to the same

size.

I used MDO (Medium Density Overlay) plywood for the top to

provide for more weather resistance. The MDO holds up very well in outdoor

weather, but is about twice as expensive as plywood.

Paint and Seal

|

Paint everything -- two coats

would be a good idea. |

Place a bead of silicone seal

around the surface that

the top will sit on, and let

cure before installing top. |

Screw and glue the bottom in

place -- then seal around the edges. |

Paint everything inside and out.

Home Depot had a returned gallon of this lovely color for $5. It is a

combination exterior paint and primer -- what a deal.

Seal all the edges to prevent air

infiltration.

Put a bead of silicone seal all the

way around the surface that the top will sit on and let it cure -- this forms a

sort of gasket to reduce air leakage once the top is screwed down. The top

should not be glued down, as you will want to be able to remove it.

Flip the box over, and screw and glue

the bottom to the box frame using deck screws. Seal all these edges.

Install the Insulation Board

|

Use Great Stuff polyurethane

foam in a can as adhesive

hold the insulation boards in place. |

Weight down the insulation

board until the Great Stuff

sets. |

Use Great Stuff to seal all the

edges of the panels. |

Cut out the rigid foam board

insulation panels to fit the bottom, back and sides.

Test fit them to make sure they fit

against the plywood back, bottom and sides.

Put some dabs of Great Stuff

polyurethane foam in a can on the bottom. This will act as an adhesive to

hold the insulation board in place.

Place the insulation board into the

Great Stuff, and then weight it down to let the foam cure.

The first layer on the back and sides

is 1 inch thick insulating boards (could be 1.5 inch thick) that is pushed in

between the box frame 2X4's.

A 2nd layer of foam board will be

installed inside this.

|

Installing the 2nd layer of foam board

insulation |

Us clamps and sticks to hold

the insulation board in

place until the foam cures. |

Note that the 2nd layer of bottom insulation must leave room for the

glazing in front of it. |

Now add a 2nd layer of 2 inch thick

rigid foam board over the bottom, sides and back.

Use the Great Stuff as adhesive in

the same way as the first layer.

If this seems like a lot of

insulation, you may be right -- see the discussion at the end on insulation

levels.

I used a mix of insulation board

types because I had some of the grey polyisocyanurate insulation left over.

The extruded polystyrene (usually pink or blue) is probably a good choice for

this application, since it is very resistant to absorbing moisture, and will

keep its insulation value even in wet or moist situations.

Install the Collector Glazing

This tank uses two layers of SunTuf

glazing on the south tank wall. The sun shining through the glazing onto

the black painted tank wall heats the water significantly on a day with sun.

The double glazing reduces the heat loss at night to about half what it would be

for single glazing.

|

This shows how the inside

layer of SufTuf glazing is installed.

The board along the top of

the glazing holds the glazing

securely in place against the frame --

it is screwed through the glazing

into the 2X4 frame.

|

The outer layer of glazing is

held in place with a clamping

strip that is screwed through

the glazing to the underlying

2X4 frame. |

Both layers of glazing installed with

the clamping strips. Note the Great

Stuff foam used to fill the gap between

the bottom insulation and inside glazing. |

Completed box -- ready to install the galvanized tank and the lid.

Note that the last corrugation

on the left and the last corrugation on the right have 3/4 by 3/4 inch (true

size) vertical strips of wood that seal up and support the edge of the glazing.

Install the Tank and Top

|

Paint the side of the tank that

will face the glazing with high

temperature flat black BBQ paint.

Two coats will likely be needed. |

Place the tank in the box with

the back against the back

insulation board. There should be

roughly a couple inches between

the glazing and the tank wall. |

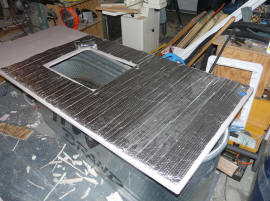

The Reflectix insulation being

applied to the bottom of the

cover. |

Paint the side of the tank that will

be facing the collector glazing with black paint to make it a good solar

absorber. I use high temperature, flat black BBQ paint that most hardware

stores sell. Set the tank aside and let the paint fully dry -- if you can

put the painted side in the sun for a day that will help fully cure the paint.

Place the tank in the box with the

back of the tank against the back of the box. There should be an inch or 2

or 3 between the inside glazing the tank wall.

I installed a layer of the Reflectix

bubble insulation on the underside of the cover. The idea is that the

Reflectixs will help to reduce radiation losses from the water surface and also

provide a better seal between the cover and box -- besides, I had it on hand :)

The top is secured with 10 deck

screws to allow it to be removed easily.

The finished stock tank in the shop.

Stuff fiberglass insulation in the

open areas to insulate further and

reduce air circulation.

First fill.

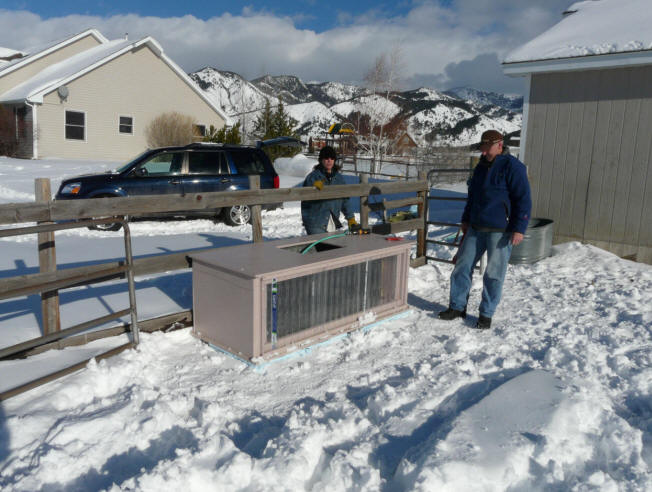

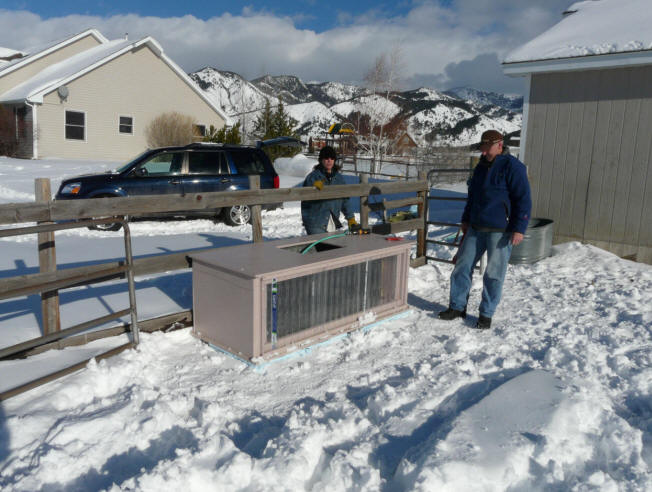

Preparing a Place for the Tank

Prepare a place for the tank to sit. A good way to do

this would be to make

a bed for the tank of a few inches of washed gravel -- this would keep it out of

the mud. The collector side of the tank must face rough south -- anywhere

from SW to SE is ok.

Since we did not get the tank done

until mid winter, there was snow on the ground when it was placed. We

put some foam board scraps under the tank to keep it off the snow a bit.

As the snow melted in the spring, the tank settled unevenly and now sits at a

bit of an angle.

Gary March 15, 2009